Center for Engineered Materials and Manufacturing (CEMM)

Our Projects

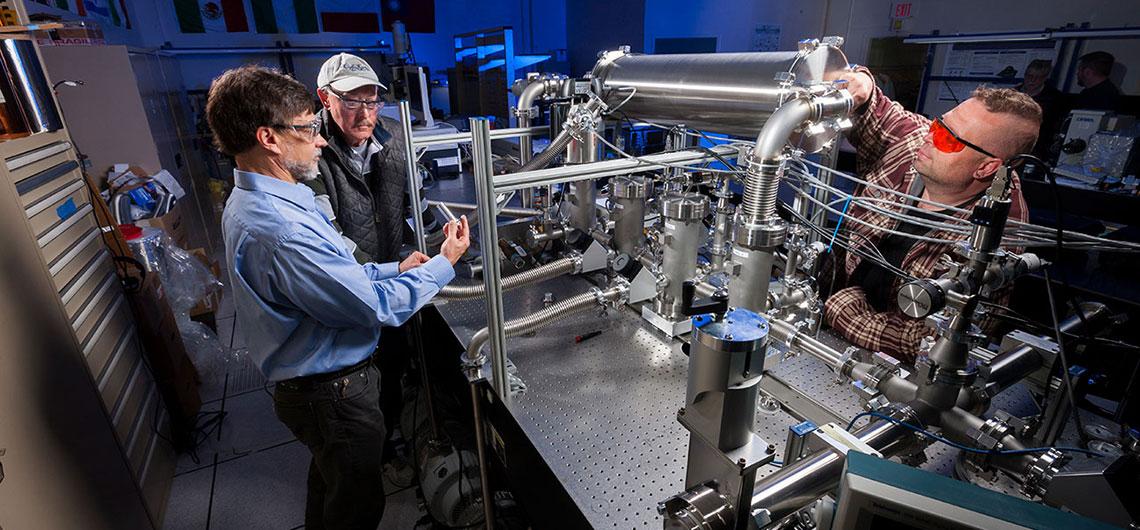

CEMM has an outsized role in the development of additive manufacturing techniques and technologies to create structural and functional materials for applications ranging from defense to energy, infrastructure, medicine and beyond. The center leverages knowledge from across disciplines to be a pathfinder in all areas of the field: tools and process development, materials synthesis and processing, architecture design and optimization and characterization of product properties.

Please do not alter or edit this area. This generates the image borders.

border-box-0

border-box-1

border-box-2

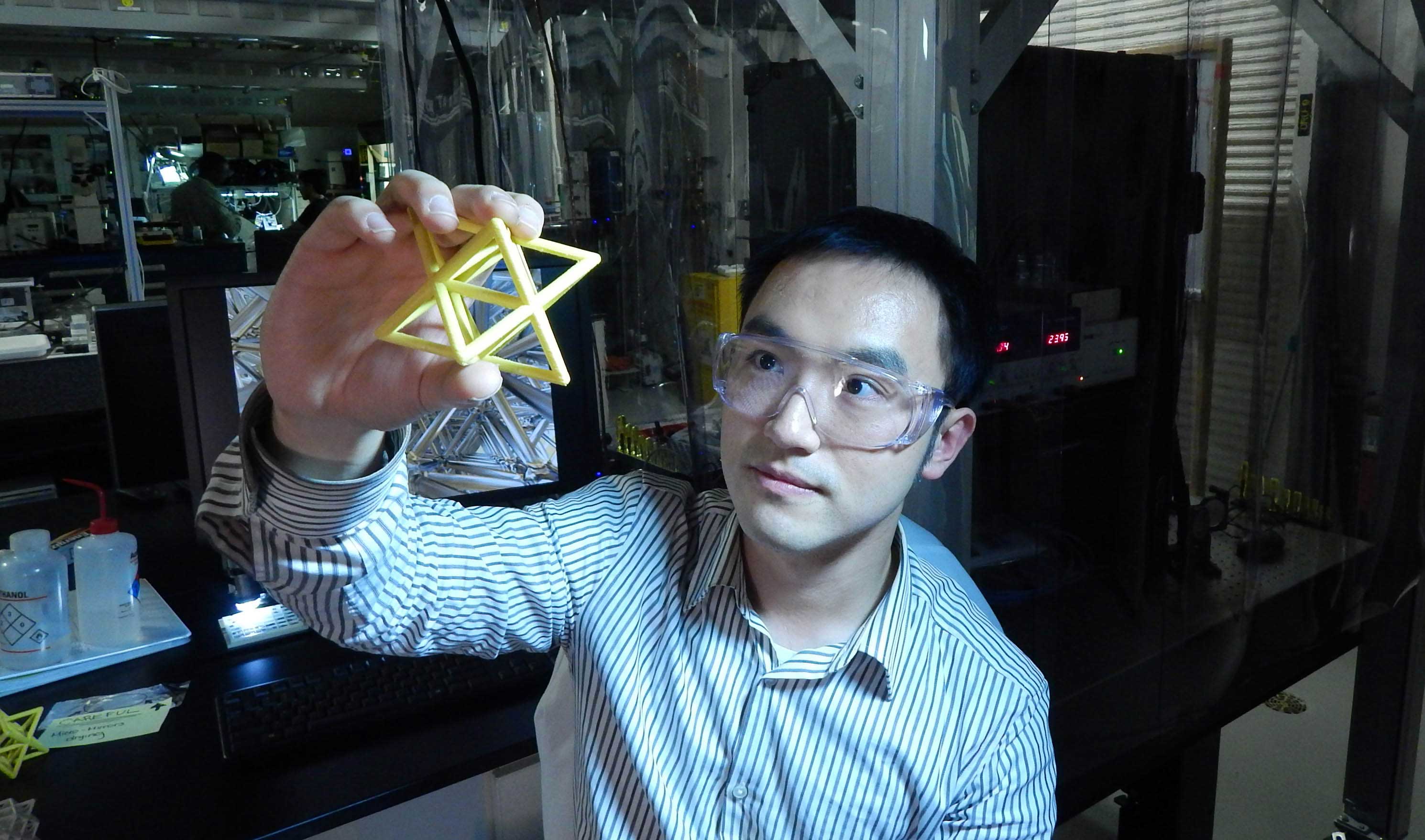

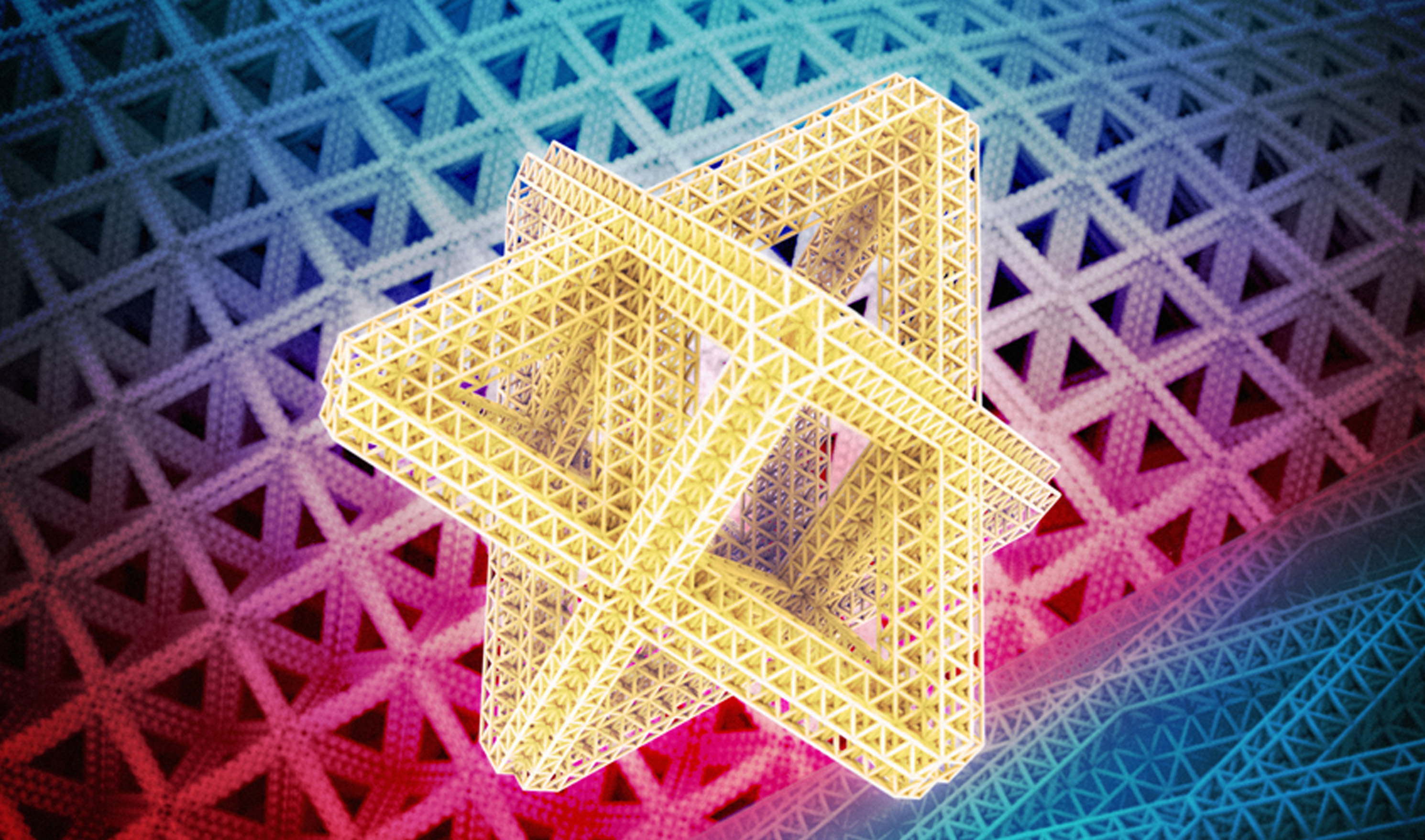

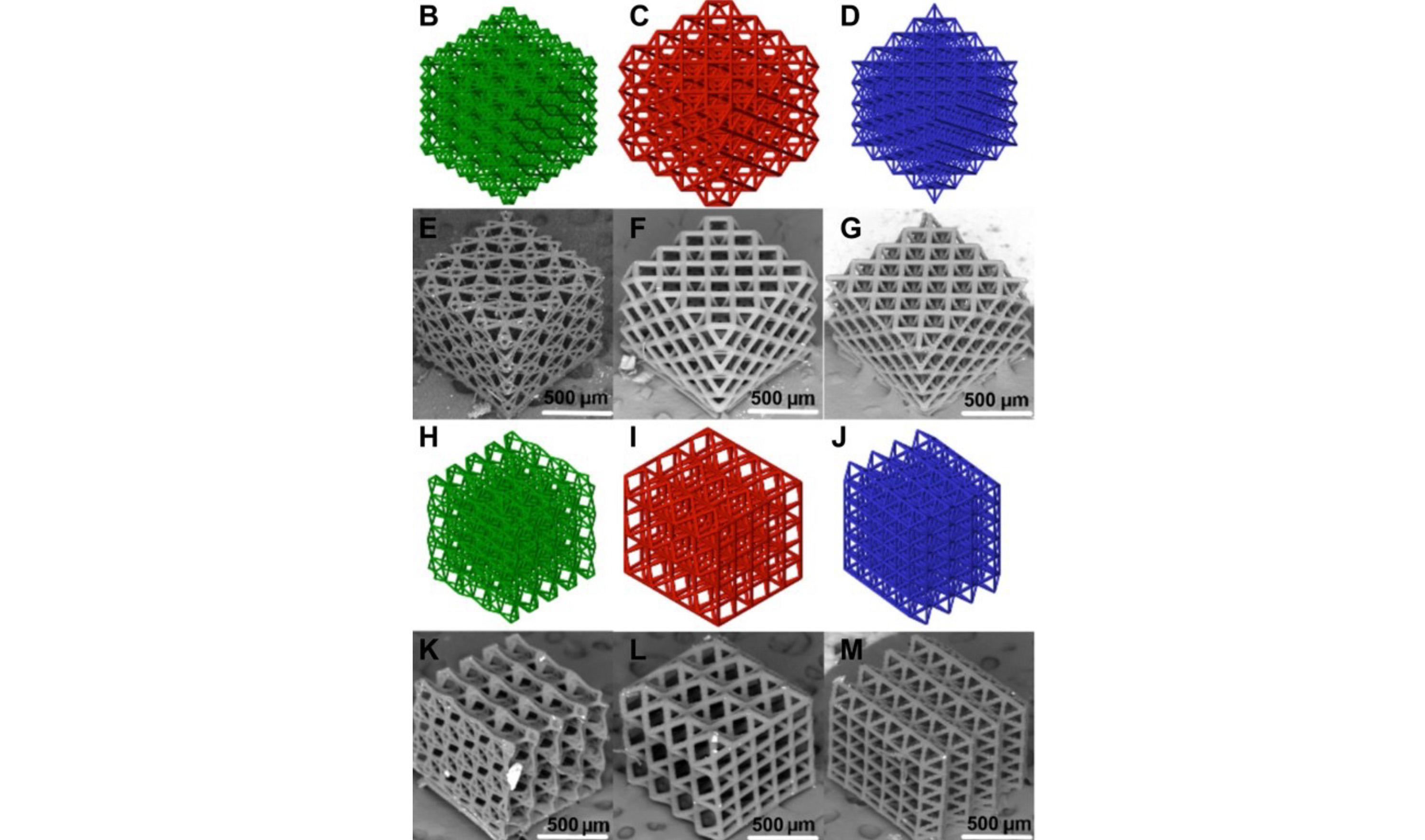

Ultralight, Ultrastiff Materials

CEMM researchers are printing aerogel-like materials that can withstand up to 160,000 times their own weight while maintaining a nearly constant stiffness per unit mass density. These materials could have a profound impact on the aerospace and automotive industries, as well as other applications where lightweight, high-stiffness and high-strength materials are needed. Read more coverage

Ultralight, Ultrastiff Materials

CEMM researchers are printing aerogel-like materials that can withstand up to 160,000 times their own weight while maintaining a nearly constant stiffness per unit mass density. These materials could have a profound impact on the aerospace and automotive industries, as well as other applications where lightweight, high-stiffness and high-strength materials are needed.

Most lightweight cellular materials have mechanical properties that degrade substantially with reduced density because their structural elements are more likely to bend under applied load. The team's metamaterials, however, exhibit ultrastiff properties across more than three orders of magnitude in density.

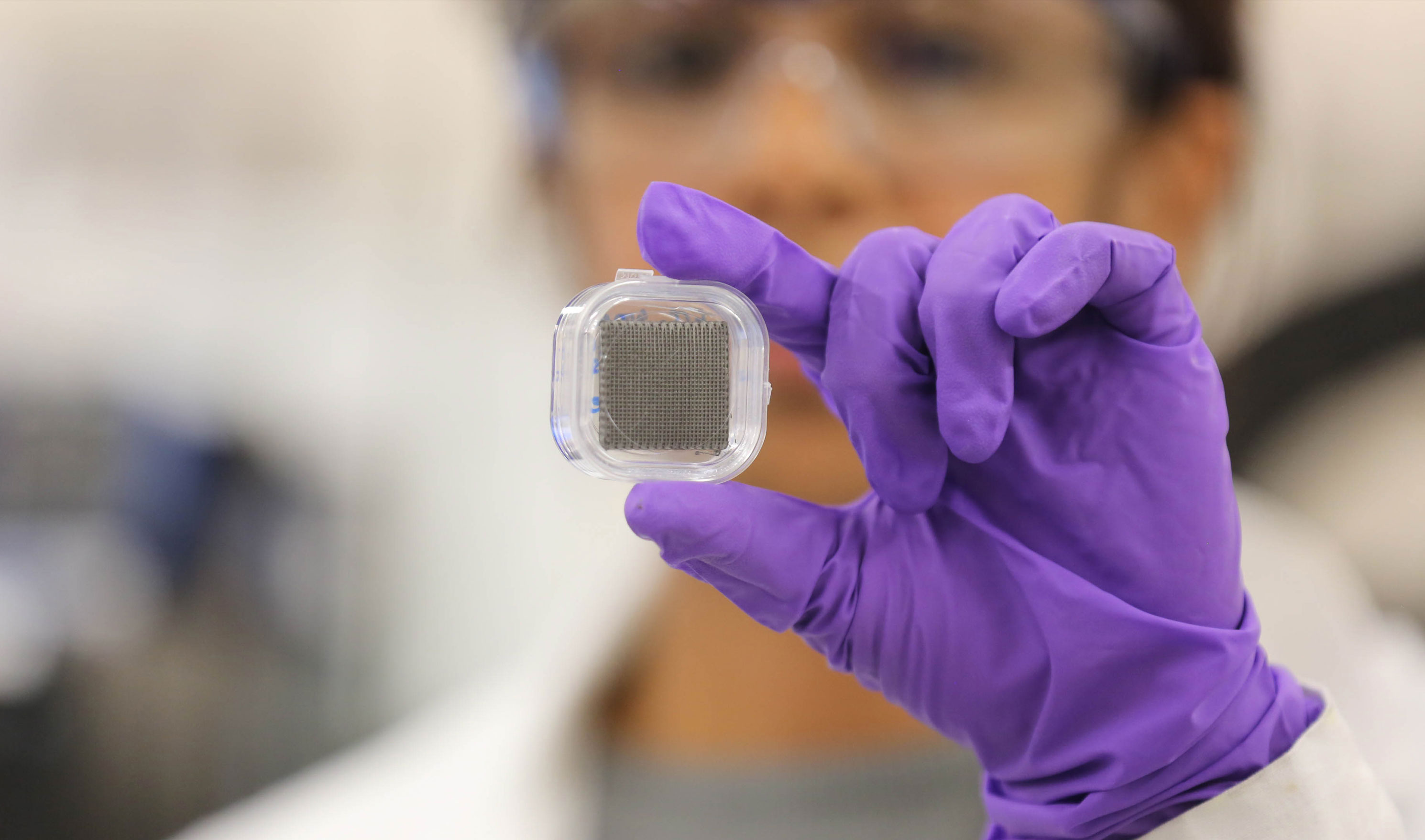

To fabricate these materials, the team uses projection microsterolithogtaphy, an additive micro-manufacturing process involves using a micro-mirror display chip to create high-fidelity 3D parts one layer at a time from photosensitive feedstock materials. It allows the team to rapidly generate materials with complex 3D micro-scale geometries that are otherwise challenging or in some cases, impossible to fabricate. The team is able to build microlattices out of polymers, metals, and ceramics.

Read more:

Relevant publications:

- “Ultralight, Ultrastiff Mechanical Metamaterials” (2014)

- Zhu, Cheng, et al. "Highly compressible 3D periodic graphene aerogel microlattices." Nature communications 6.1 (2015): 1-8.

- “Supercapacitors Based on Three Dimensional Hierarchical Graphene Aerogels with Periodic Macropores” (2016) – Zhu et al Link

- Liu, Tianyu, et al. "Ion Intercalation Induced Capacitance Improvement for Graphene‐Based Supercapacitor Electrodes." ChemNanoMat 2.7 (2016): 635-641.

- Qi, Zhen, et al. "3D‐Printed, Superelastic Polypyrrole–Graphene Electrodes with Ultrahigh Areal Capacitance for Electrochemical Energy Storage." Advanced Materials Technologies 3.7 (2018): 1800053.

- Yao, Bin, et al. "Efficient 3D printed pseudocapacitive electrodes with ultrahigh MnO2 loading." Joule 3.2 (2019): 459-470.

3D-Printed Optical Glass

CEMM can print transparent glass with a controlled composition and tunable optical, thermal, and mechanical properties. The materials—which are printed at room temperature to prevent residual stress and cracking— exhibit structure and compositional gradients that were previously thought impossible and open the door to a new generation of optical materials. Read more coverage

3D-Printed Optical Glass

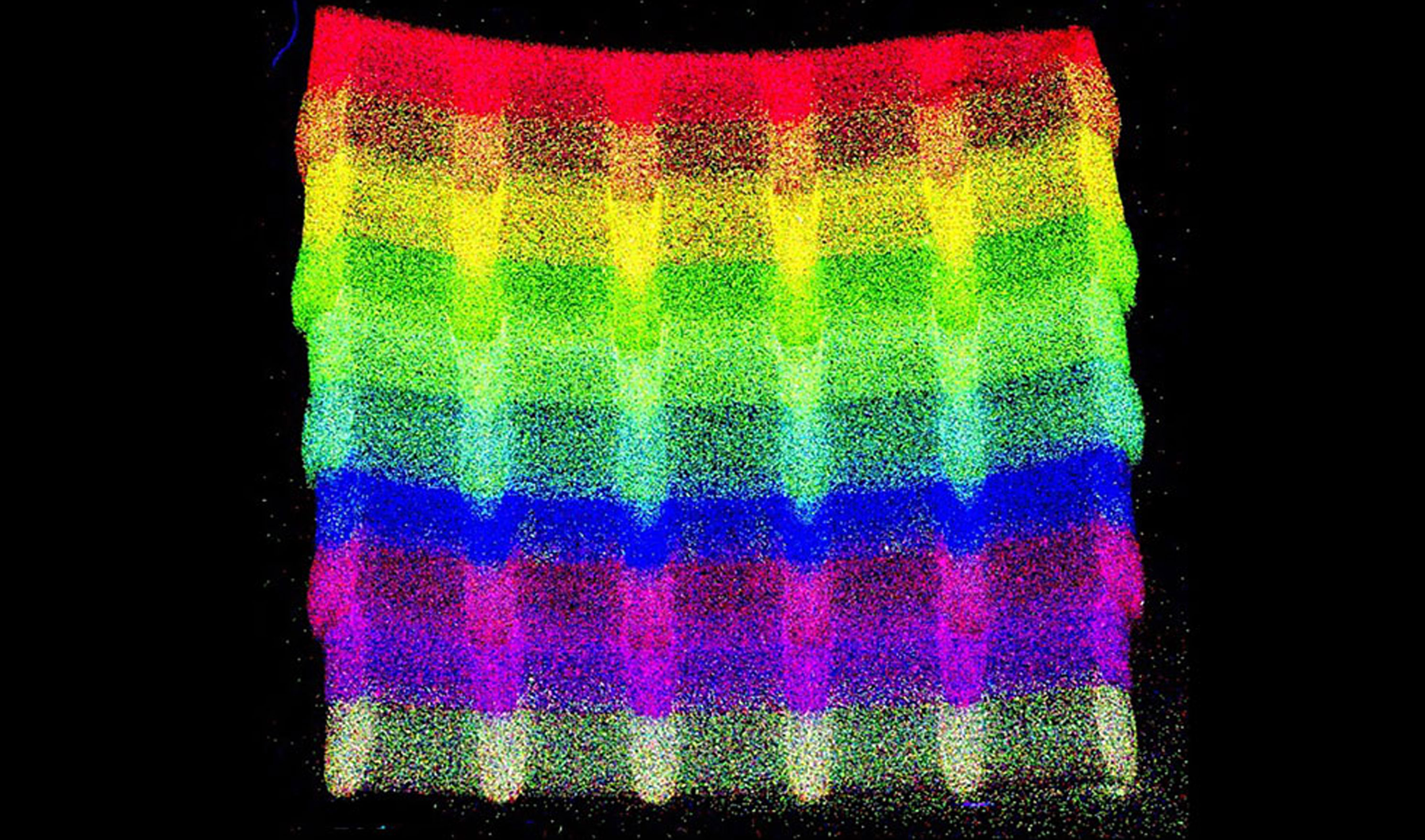

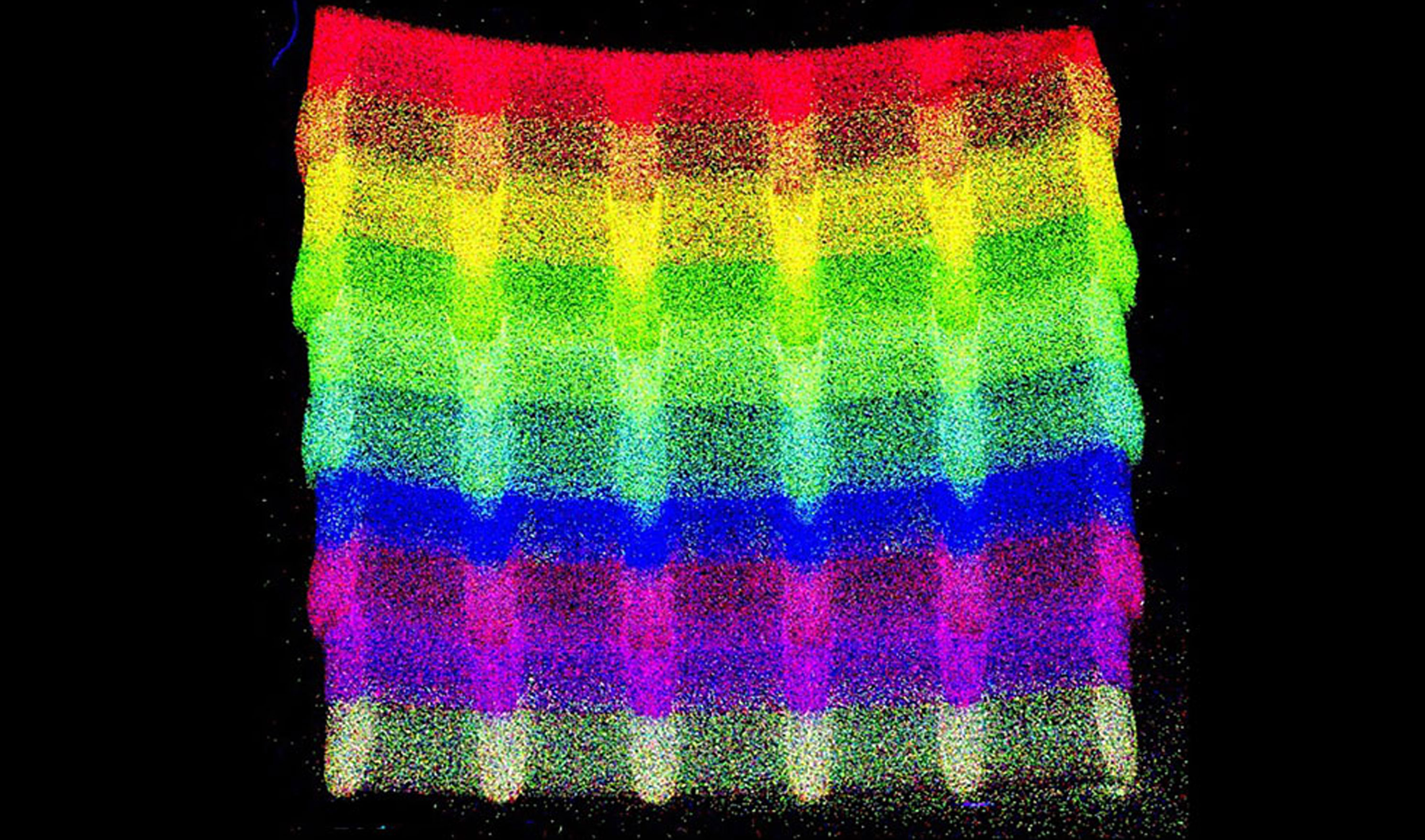

CEMM can print transparent glass with a controlled composition and tunable optical, thermal, and mechanical properties. The materials, which are printed at room temperature to prevent residual stress and cracking, exhibit structure and compositional gradients that were previously thought impossible and open the door for a new generation of optical materials.

Optical materials are used in everything from telescope lenses to lasers to consumer electronics, but conventional glassmaking can result in structural inconsistencies that can corrupt a material and its properties and make it hard to optimize. CEMM’s innovative direct ink writing (DIW) method is the first extrusion-based glass fabrication technique to offer the precision of 3D printing alongside the freedom of spatially varying optical properties. It allows researchers to fabricate glassy materials with near-unlimited flexibility in form and structure while preserving the fine features of traditional glassmaking methods.

The team has already produced an array of complex objects once unthinkable using traditional approaches. The process’s free-form flexibility enables fine lattices, solid monoliths, liquid-tight containers, and microfluidic channels, all capable of supporting smooth gradient transitions in color, density, and refractive index.

These structures could become lightweight components in airborne laser-mirror systems or refractive index-graded lenses that could reduce finishing costs up to 90 percent. Maximizing operating parameters while minimizing cost is appealing to aerospace manufacturers and collaborators. However, the utility of tailored glass goes beyond defense-related purposes—the technology promises pristine crystal glass with high refractive index and optical dispersion to increase the luster of luxury goods.

Read more:

- 3D Printing Optical-Quality Glass

- Lab breakthrough in 3D printing of glass

- Lab scientists successfully print glass optics

- 3D-printed glass enhances optical design flexibility

Relevant publications:

- Toombs, Joseph T., et al. "Volumetric additive manufacturing of silica glass with microscale computed axial lithography." Science 376.6590 (2022): 308-312.

- Dylla-Spears, Rebecca, et al. "3D printed gradient index glass optics." Science advances 6.47 (2020): eabc7429.

- Destino, Joel F., et al. "3D printed optical quality silica and silica–titania glasses from sol–gel feedstocks." Advanced Materials Technologies 3.6 (2018): 1700323.

- Nguyen, Du T., et al. "3D‐printed transparent glass." Advanced Materials 29.26 (2017): 1701181.

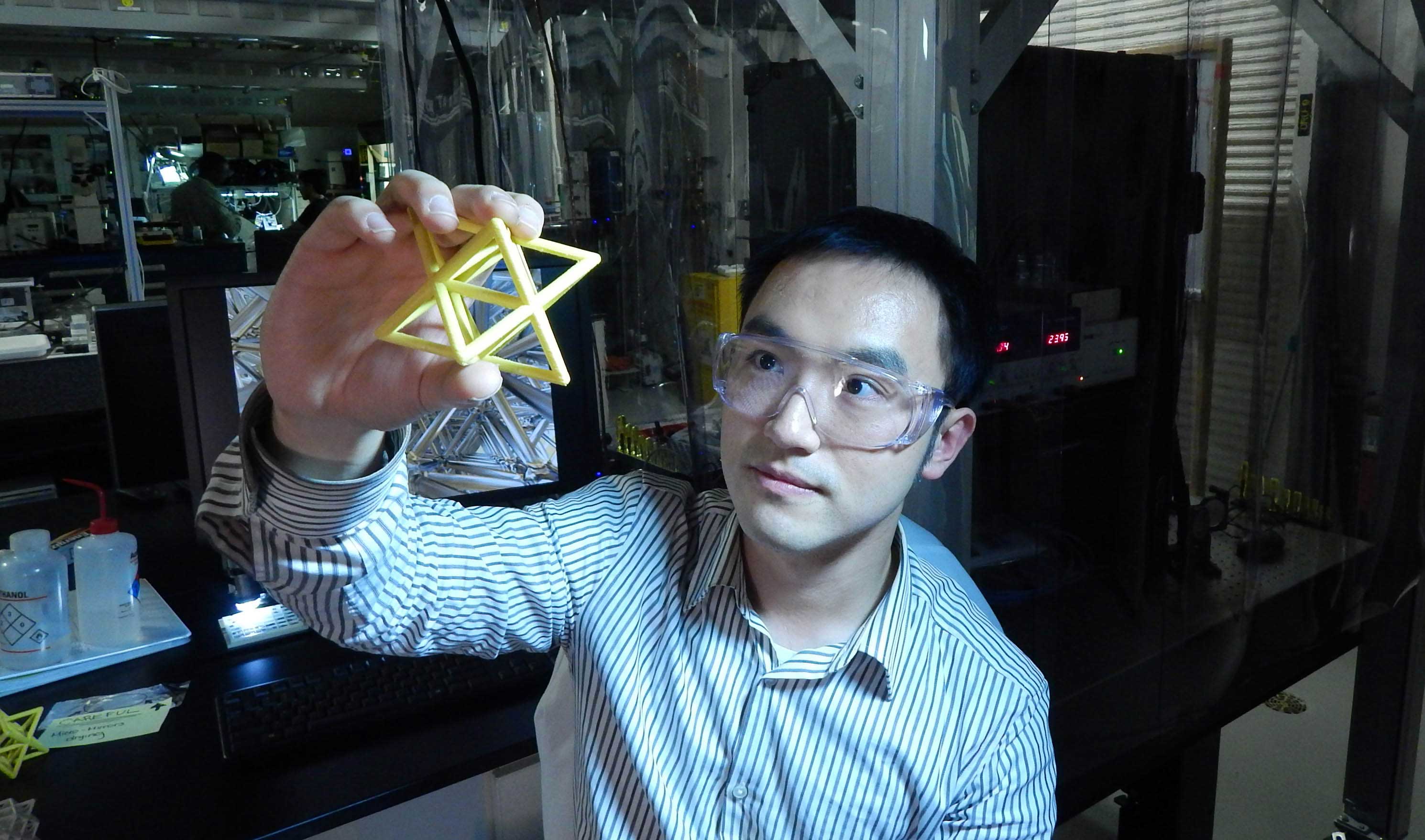

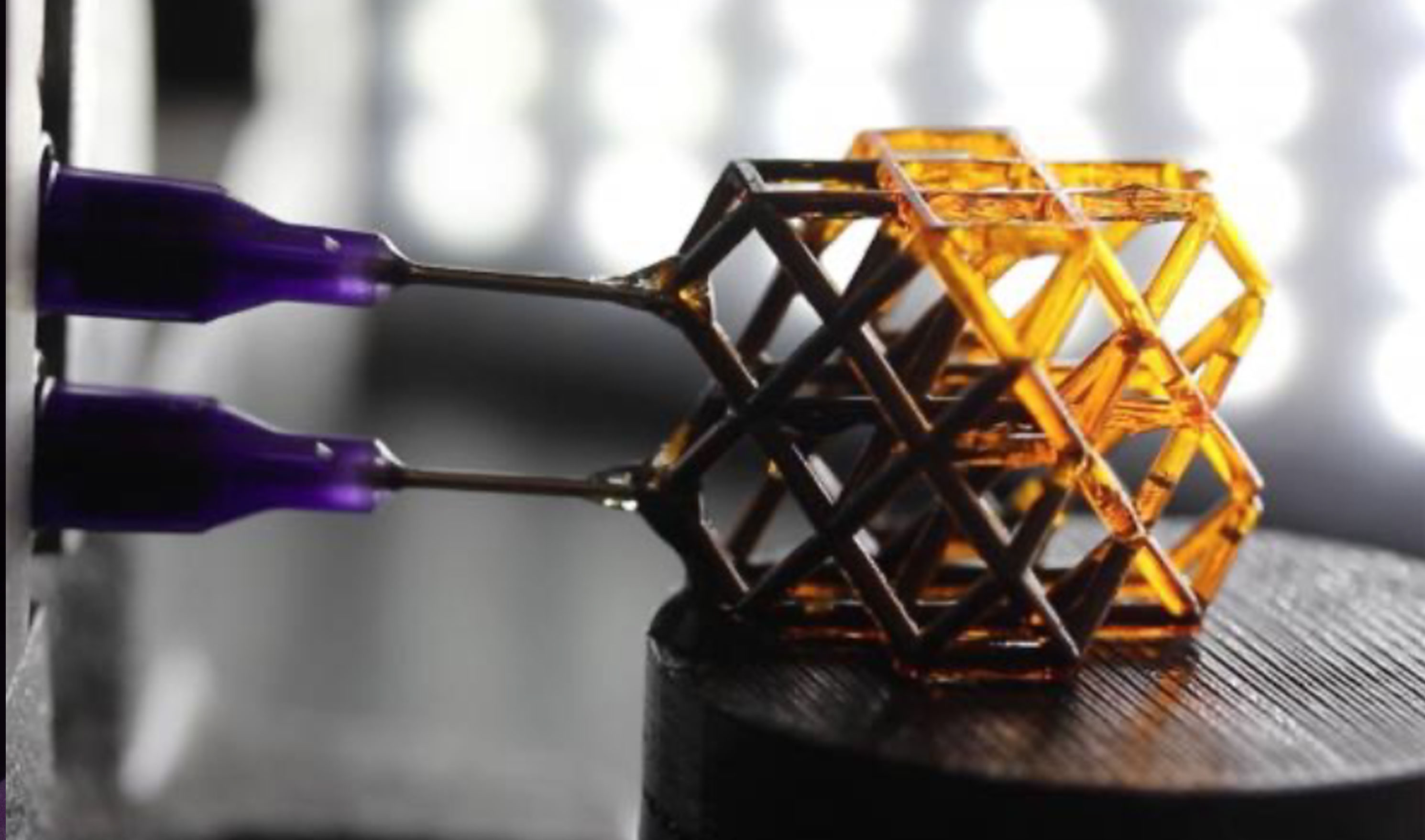

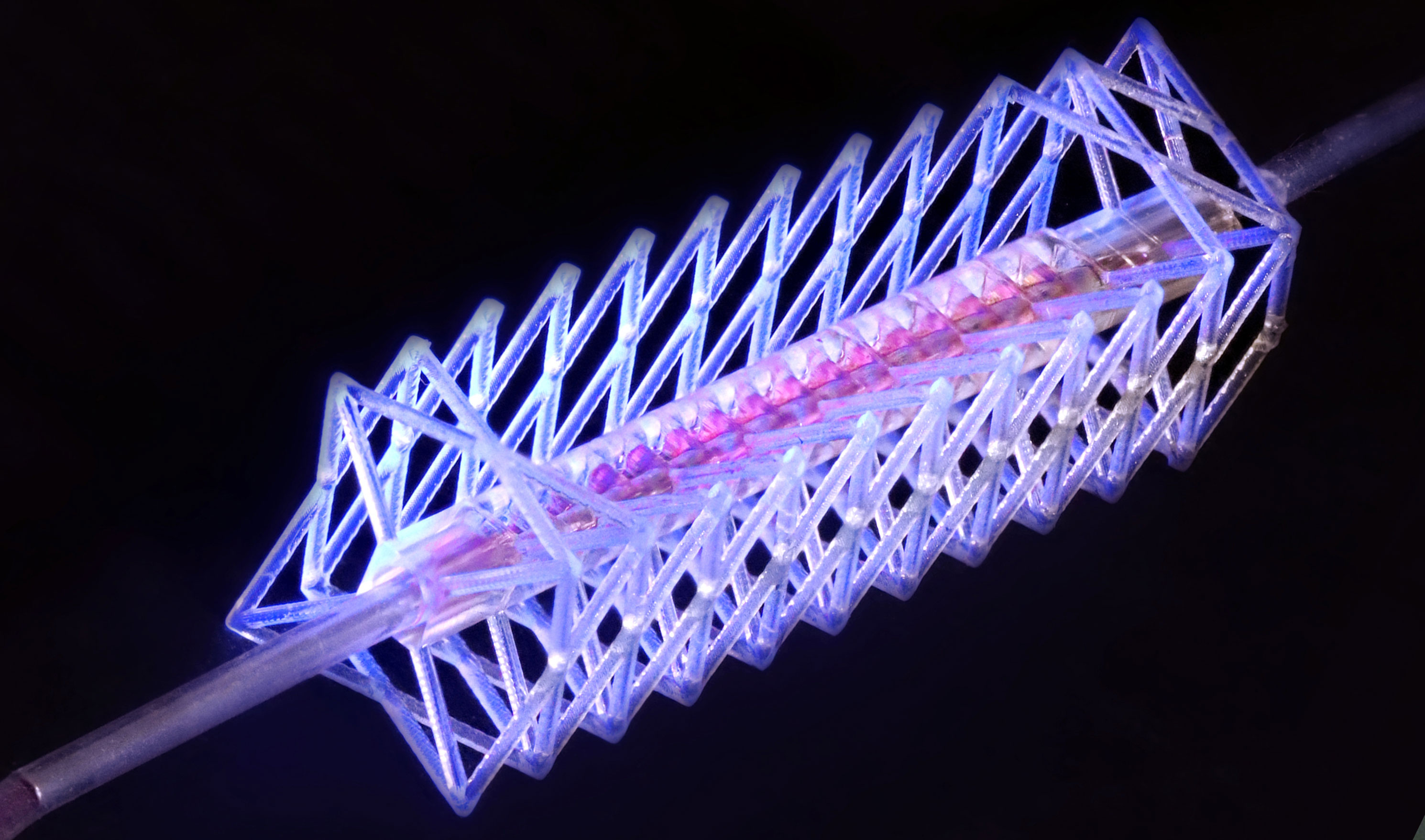

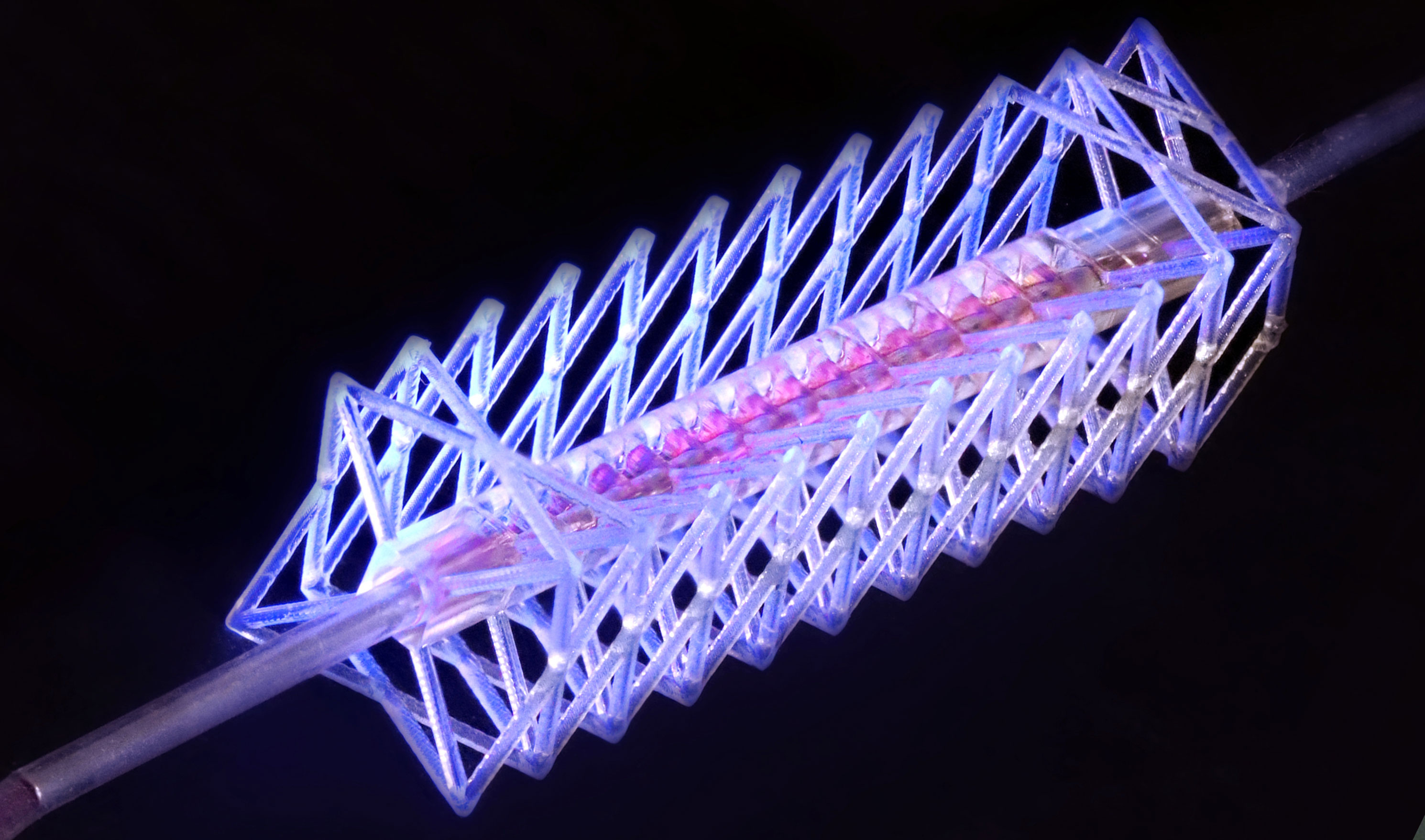

Field-Response Mechanical Metamaterials

While researchers can fabricate materials with a wide range of mechanical properties that don’t exist in nature, those properties are static, so the team considers a metamaterial that can quickly adapt its properties in response to an external stimulus as the next evolution. Read more coverage

Field-Response Mechanical Metamaterials

CEMM researchers have introduced a new class of 3D-printed metamaterials that can nearly instantly respond and stiffen when exposed to a magnetic field.

While researchers can fabricate materials with a wide range of mechanical properties that don’t exist in nature, those properties are static, so the team considers a metamaterial that can quickly adapt its properties in response to an external stimulus as the next evolution.

The materials employ a viscous, magnetically responsive fluid that is manually injected into the hollow struts and beams of 3D-printed lattices, which are built on LLNL’s Large Area Projection Microstereolithography (LAPµSL) platform. Once the fluid is inside the lattice structures, applying an external magnetic field causes the fluid to stiffen and the overall 3D-printed structures subsequently stiffen almost instantaneously.

Unlike other shape morphing materials, the overall structure does not change. The fluid’s ferromagnetic particles located in the core of the beams form chains in response to the magnetic field, which stiffens the fluid and the lattice structure as a result. This response happens in less than a second. The change is also easily reversible and highly tunable by varying the strength of the applied magnetic field.

The technology could be useful for impact absorption — for example, automotive seats could have fluid-responsive metamaterials integrated inside along with sensors to detect a crash, and seats would stiffen on impact, potentially reducing passenger motion that can cause whiplash. It also could be applied to next-generation helmets or neck braces, housing for optical components and soft robotics, among many other applications.

Read more:

Relevant publication:

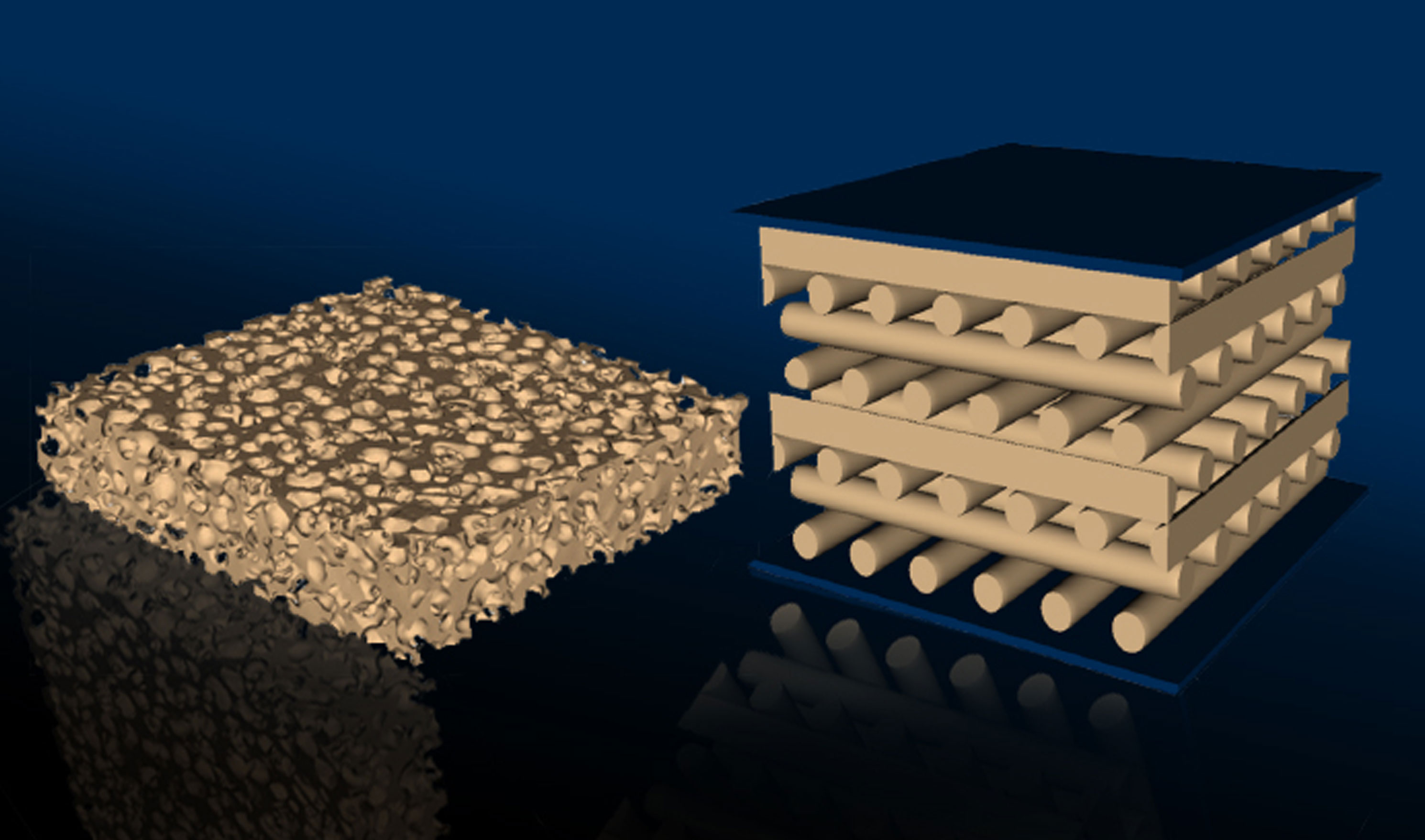

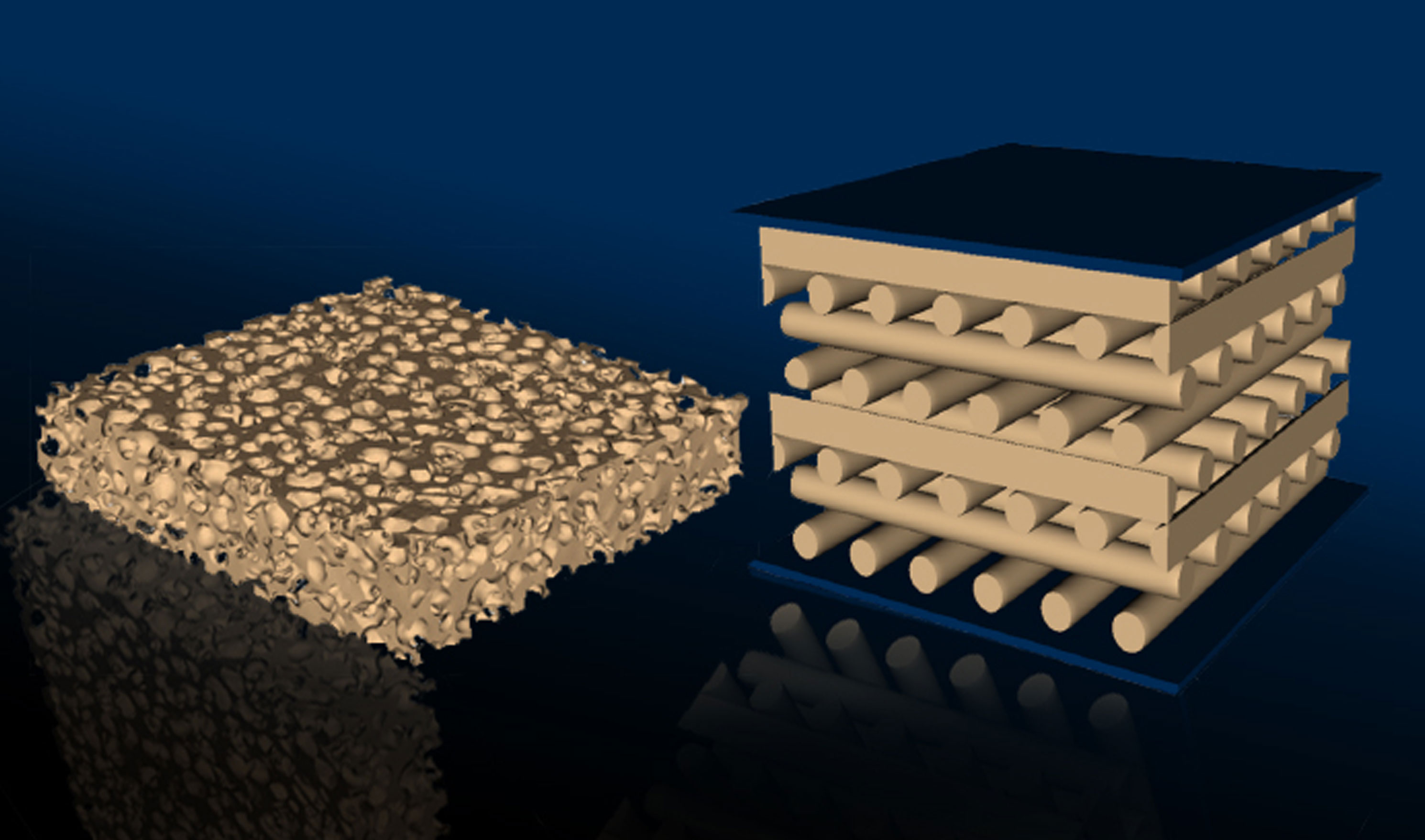

Energy Absorption Materials and 3D-Printed Foams

CEMM’s cushioning materials can absorb energy at a tunable level and overcome the performance limitations of cellular materials, gels, and traditional forms while being more uniform, consistent, and durable. As an improved alternative to traditional foam structures, CEMM’s 3D-printed materials have controlled, uniform structures and have proven to better retain their mechanical and structural characteristics. Read more coverage

Energy Absorption Materials and 3D-Printed Foams

CEMM’s cushioning materials can absorb energy at a tunable level and overcome the performance limitations of cellular materials, gels, and traditional forms while being more uniform, consistent, and durable. As an improved alternative to traditional foam structures, CEMM’s 3D-printed materials have controlled, uniform structures and have proven to better retain their mechanical and structural characteristics.

Foams, also known as cellular solids, have applications ranging from thermal insulation and shock-absorbing support cushions to lightweight structural and floatation components. Traditionally, foams are created by processes that lead to a highly non-uniform structure with significant dispersion in size, shape, thickness, connectedness and topology of its constituent cells. However, CEMM can print these materials with predictable structure and performance under both compression and shear.

CEMM reseachers constructed cushions using two different configurations using a direct ink writing process: one in an inline stacked configuration and the other in a staggered configuration. The stacked architecture is stiffer in compression and, with increased compression, undergoes a buckling instability. The staggered architecture is softer in compression and undergoes more of a bending type of deformation. The stacked structure has solid columns of material beneath it to offer more support, while the staggered structure has voids under each filament that offer much less resistance to compression.

The researchers envision using their novel energy absorbing materials in many applications, including shoe and helmet inserts, protective materials for sensitive instrumentation and in aerospace applications to combat the effects of temperature fluctuations and vibration.

Read more:

- “3D-printed foam outperforms standard materials” (2016)

- “Livermore researchers create engineered energy absorbing material” (2014)

Relevant publications:

- Maiti, A., et al. "3D printed cellular solid outperforms traditional stochastic foam in long-term mechanical response." Scientific reports 6.1 (2016): 1-9.

- Duoss, Eric B., et al. "Three‐dimensional printing of elastomeric, cellular architectures with negative stiffness." Advanced Functional Materials 24.31 (2014): 4905-4913.

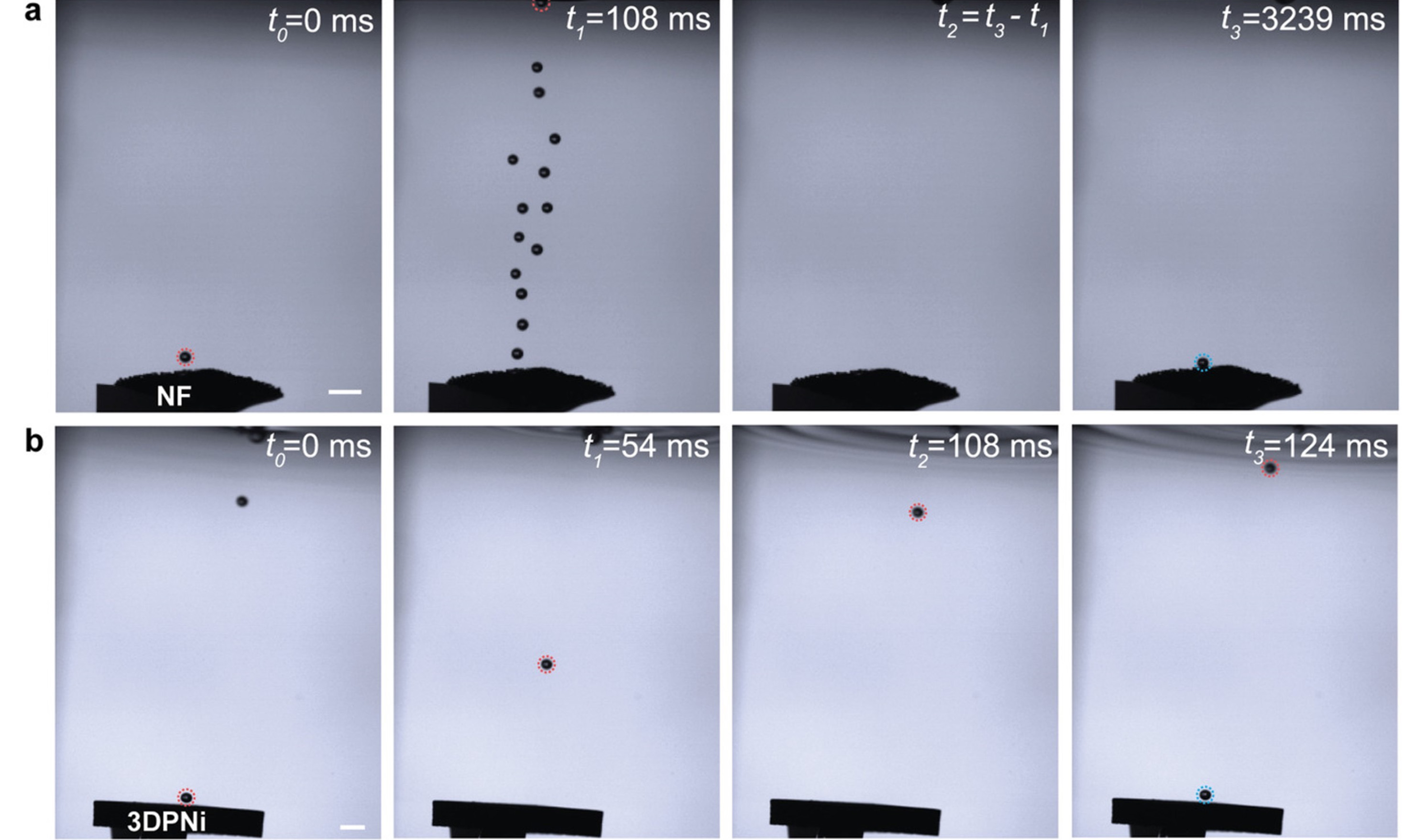

Catalytic Materials

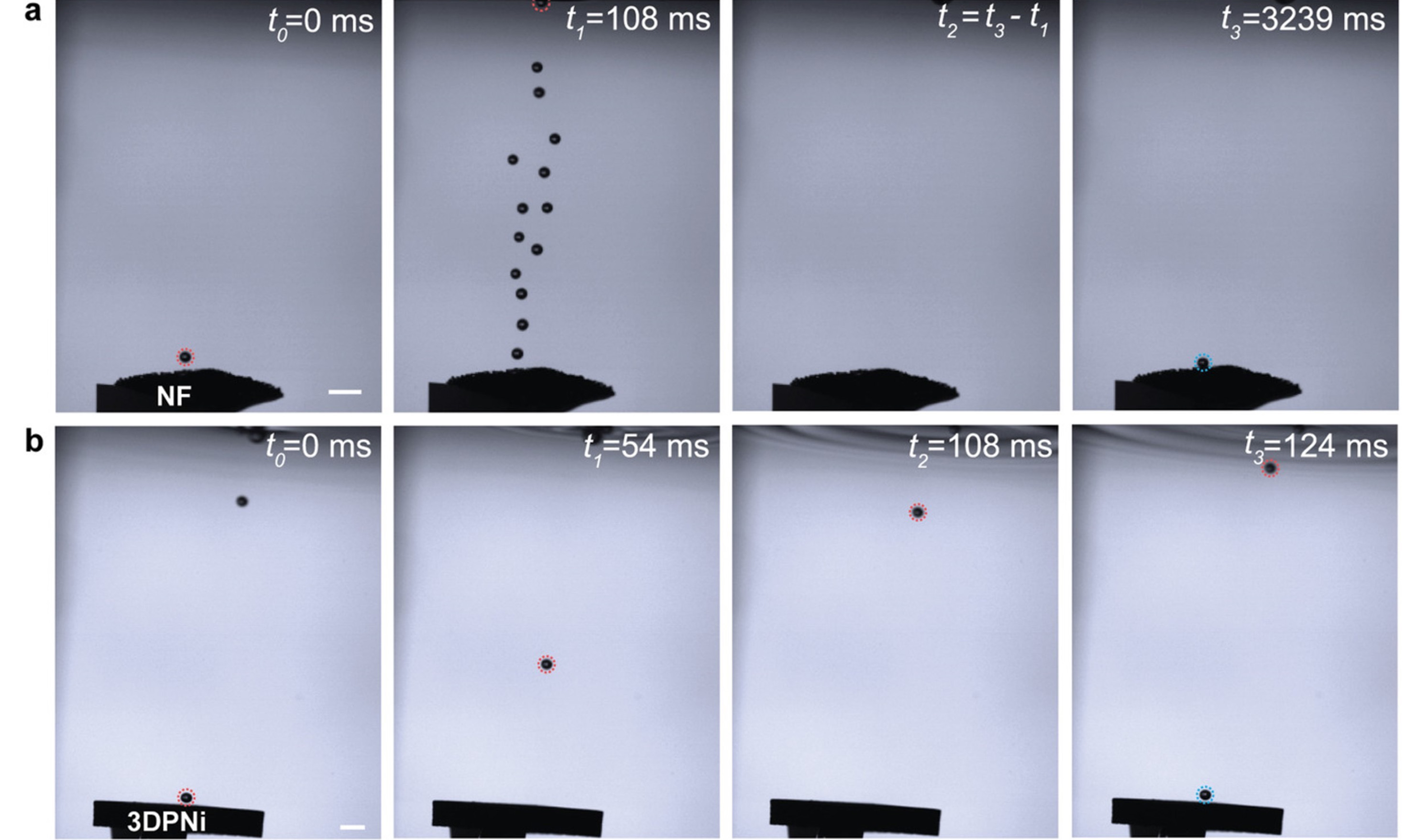

At high current densities, alkaline water electrolysis generates gas bubbles that can get stuck in the pores of Nickel electrodes and block active sites for catalysts. To solve this problem, CEMM researchers developed and additively manufactured Ni electrodes with periodic structures that facilitates bubble transport and release, which prevents them from getting trapped and makes the process more efficient. Read more coverage

Catalytic Materials

At high current densities, alkaline water electrolysis generates gas bubbles that can get stuck in the pores of Nickel electrodes and block active sites for catalysts. To solve this problem, CEMM researchers developed and additively manufactured Ni electrodes with periodic structures that facilitates bubble transport and release, which prevents them from getting trapped and makes the process more efficient.

In another project, CEMM researchers printed fluoropolymer gas diffusion layers with tunable micropore characteristics, macroscale structures and surface morphology that make the CO2 reduction reaction much more effective and efficient. The materials could accelerate CO2 capture as an alternative to fossil fuels while providing a platform for designing new catalytic materials for the process.

Relevant publications:

- Wicks, Joshua, et al. "3D‐Printable Fluoropolymer Gas Diffusion Layers for CO2 Electroreduction." Advanced Materials 33.7 (2021): 2003855.

- Kou, Tianyi, et al. "Periodic Porous 3D Electrodes Mitigate Gas Bubble Traffic during Alkaline Water Electrolysis at High Current Densities." Advanced Energy Materials 10.46 (2020): 2002955.

Cellular Fluidics

Inspired by the way plants absorb and distribute water and nutrients, CEMM researchers developed a groundbreaking method for transporting liquids and gases using 3D-printed lattice design and capillary action phenomena. Read more coverage

Cellular Fluidics

Inspired by the way plants absorb and distribute water and nutrients, CEMM researchers developed a groundbreaking method for transporting liquids and gases using 3D-printed lattice design and capillary action phenomena. The method, known as cellular fluidics, involves 3D-printing micro-architected structures capable of containing and flowing fluids to create extensive and controlled contacts between liquids and gases.

The ordered, porous and open-cell structures facilitate surface tension-driven capillary action (the movement of liquid though small pores due to adhesion and cohesion forces) in the unit cells — akin to a tree pulling water from soil or a paper towel soaking up a spill — and enable liquid and gas transport throughout the structures.

Leveraging years of Lab research into 3D-printed, hierarchical lattice design and LLNL-developed Large Area Projection Micro-stereo Lithography (LAPuSL) technology — a light-based printer that can produce extremely tiny features over a large scale — researchers built various fluid-filled structures to study different kinds of multiphase transport and reaction phenomena.

Researchers said the breakthrough technique could have transformative and broad-ranging impacts on numerous fields involving multiphase (gas/liquid/solid) processes, including electrochemical or biological reactors used to convert carbon dioxide or methane to energy, advanced microfluidics, solar desalination, air filtration, heat transfer, transpiration cooling and the delivery of fluids in low- or zero-gravity environments.

In addition, cellular fluidics concepts could improve current microfluidics technology by allowing for controlled fluid transport in complex geometries in 3D. It also showed promise for applications in outer space, where it would allow for fluid transport in the absence of gravity, and in aerosol sample collection and gas filtration, due to the ability to precisely control contact between liquid and gas phases. The concepts could also improve heat transfer by incorporating lattice designs that allow structures to remain cooled over extended periods of time.

Read more:

Relevant publications:

- Dudukovic, N.A., Fong, E.J., Gemeda, H.B. et al. Cellular fluidics. Nature 595, 58–65 (2021). https://doi.org/10.1038/s41586-021-03603-2

Next-Generation Lightweight Supercapacitors

CEMM researchers have successfully 3D-printed supercapacitors using an ultra-lightweight graphene aerogel, opening the door to novel, unconstrained designs of highly efficient energy storage systems for smartphones, wearables, implantable devices, electric cars and wireless sensors. Read more coverage

Next-Generation Lightweight Supercapacitors

CEMM researchers have successfully 3D-printed supercapacitors using an ultra-lightweight graphene aerogel, opening the door to novel, unconstrained designs of highly efficient energy storage systems for smartphones, wearables, implantable devices, electric cars and wireless sensors.

CEMM’s printed graphene-based aerogels are much smaller, thinner and more lightweight than other supercapacitors and show record performance in terms of storage, capacity and charging speed. The materials could revolutionize energy storage, solve the traditional trade-off of charging speed and storage in supercapacitor design and enable a new generation of energy-efficient storage.

Using a direct-ink writing and a graphene-oxide composite ink designed at the Lab, the team was able to print micro-architected electrodes and build supercapacitors able to retain energy on par with those made with electrodes 10 to 100 times thinner.

The supercapacitors also can charge incredibly fast, in theory requiring just a few minutes or seconds to reach full capacity. They’ve since doubled their performance by sandwiching a lithium ion and a percholorate ion between layers of graphene in aerogel electrodes. The devices’ capacity has substantially improved while maintaining an excellent rate capability.

The next step is creating more complex architectures using aerogels, enabling more powerful supercapacitors that could someday be used in custom-built electronics.The researchers believe the 3D-printed supercapacitors will be used to create unique electronics that are currently difficult or even impossible to make using other synthetic methods, including fully customized smartphones and paper-based or foldable devices, while achieving unprecedented levels of performance.

Read more:

- Lawrence Livermore team improves 3D-printed graphene aerogel supercapacitors

- Researchers 3D print ultralight supercapacitors

- Research team achieves record performance for 3D-printed graphene aerogel supercapacitors

- 3D-printed aerogel electrodes boost energy storage

Relevant publications:

- Zhu et al. “Supercapacitors Based on Three Dimensional Hierarchical Graphene Aerogels with Periodic Macropores.” Nano Letters 16.6 (2016): 3448–3456.

- Liu, Tianyu, et al. "Ion Intercalation Induced Capacitance Improvement for Graphene‐Based Supercapacitor Electrodes." ChemNanoMat 2.7 (2016): 635-641.

- Qi, Zhen, et al. "3D‐Printed, Superelastic Polypyrrole–Graphene Electrodes with Ultrahigh Areal Capacitance for Electrochemical Energy Storage." Advanced Materials Technologies 3.7 (2018): 1800053.

- Yao, Bin, et al. "Efficient 3D printed pseudocapacitive electrodes with ultrahigh MnO2 loading." Joule 3.2 (2019): 459-470.

Biomaterials

For the first time, CEMM was able to print bacterial biofilms using projection microstereolithography. The printed biofilms allow researchers to make complex structured cultures of microbes in a controlled and reproducible way, opening the door to new studies on microbial behavior and environmental response, as well as advances in biotechnology and environmental remediation. Read more coverage

Biomaterials

For the first time, CEMM was able to print bacterial biofilms using projection microstereolithography. The printed biofilms allow researchers to make complex structured cultures of microbes in a controlled and reproducible way, opening the door to new studies on microbial behavior and environmental response, as well as advances in biotechnology and environmental remediation.

With these sophisticated structures, researchers will be able to conduct controlled experiments to extend basic scientific understanding of microbial interaction from the flat, unnatural setting of Petri dishes to dynamic, 3D environments that reflect natural patterns.

Previous efforts to characterize the biodiversity and community stability of micro-environments have been constrained by lack of control over growth geometry. Microbes systematically grown on the same agar resort to interspecies competition over nutrients rather than expand in new directions to exhibit colony spacing and nuanced biological relationships. Exerting precise control over microbial cultures in increasingly complex settings will reveal insights into behaviors that have so far eluded researchers.

Harnessing microbes’ natural metabolic processes will hasten the development of new technologies across diverse fields. By exploiting special metabolic processes—oftentimes via fermentation—bioplastics and energy-rich biofuels such as ethanol and biodiesel could be more efficiently derived from biomass, relieving dependence on finite petroleum resources.

Encasing cells in printed bioresins could effectively capture and neutralize pollutants as part of bioremediation efforts in contaminated areas. Similarly, printed microbial structures could be used to absorb and purify rare-earth elements during mining operations, a capability that promotes resource independence.

Read more:

Relevant publications:

- Dubbin, Karen, et al. "Projection microstereolithographic microbial bioprinting for engineered biofilms." Nano Letters 21.3 (2021): 1352-1359.

- Qian, Fang, et al. “Direct Writing of Tunable Living Inks for Bioprocess Intensification.” Nano Letters 19.9 (2019): 5829–5835

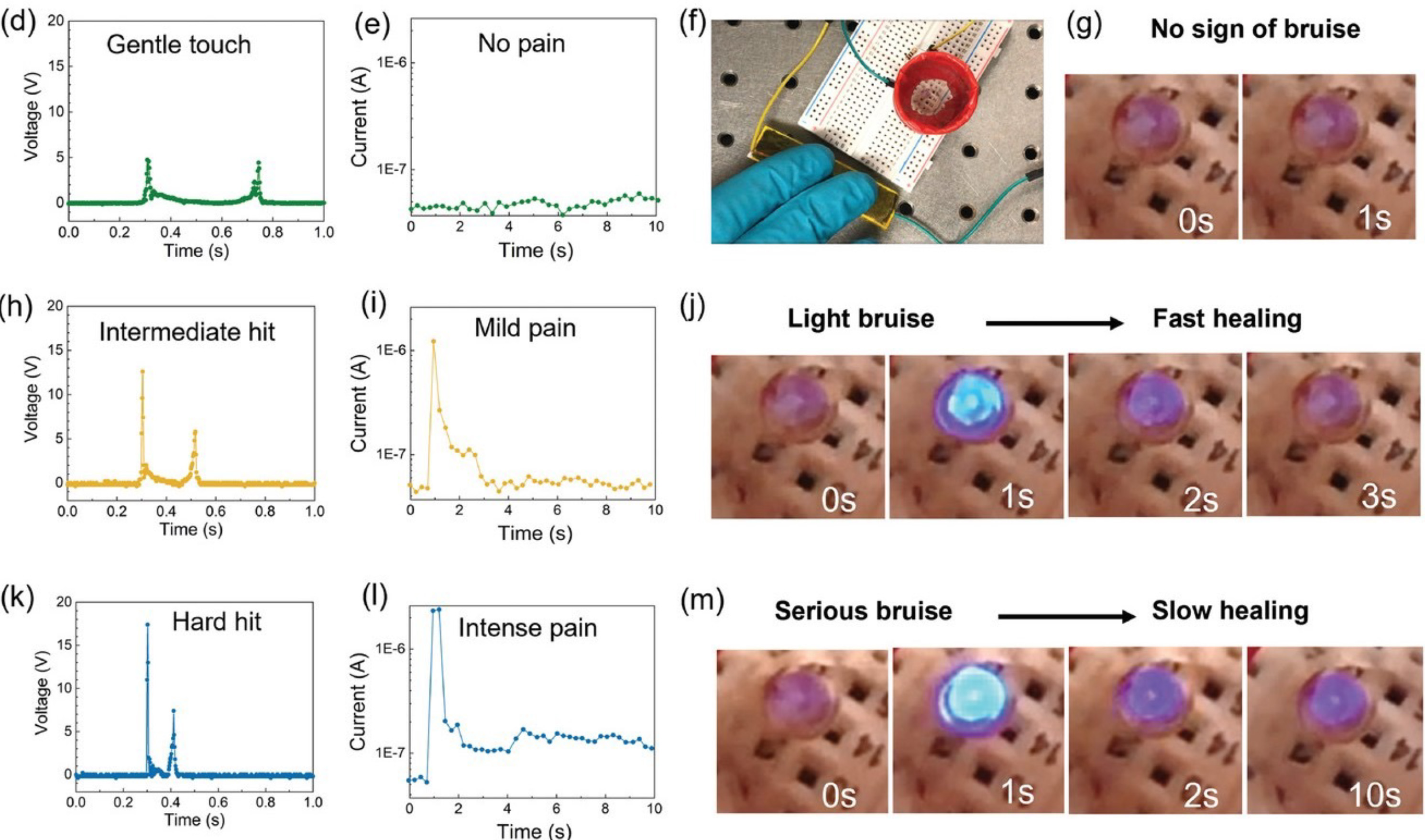

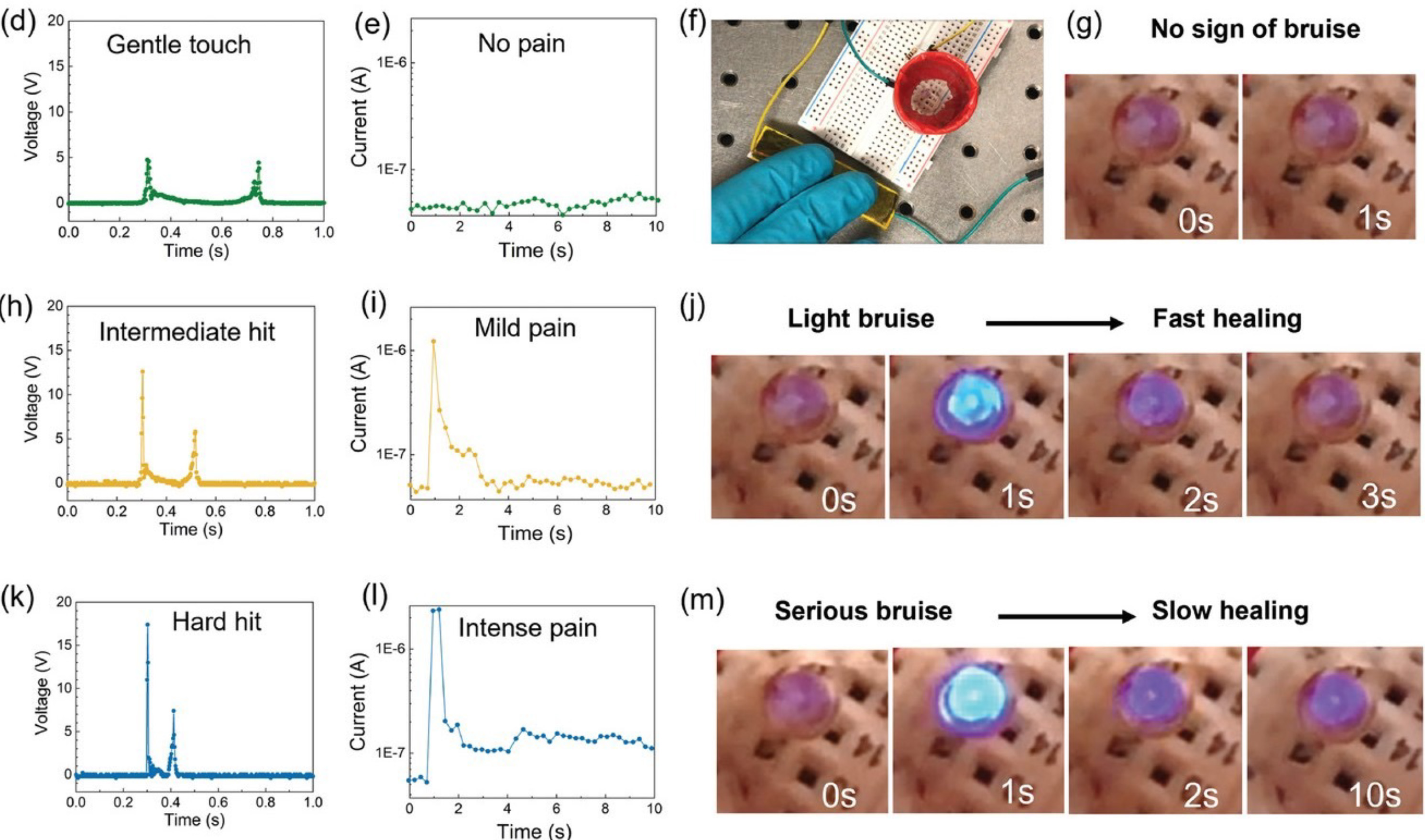

An Electronic Injury Response System

CEMM designed and printed a piece of artificial skin mechanically mimic the body’s injury response and healing process. Using a combination of uses memristors, LEDs and a triboelectric generator, the device can sense pain, show signs of injury and eventually heal the way real skin does. Read more coverage

An Electronic Injury Response System

CEMM designed and printed a piece of artificial skin mechanically mimic the body’s injury response and healing process. Using a combination of uses memristors, LEDs and a triboelectric generator, the device can sense pain, show signs of injury and eventually heal the way real skin does.

Relevant publication:

- Xu, Xiaojie, et al. "A Bioinspired Artificial Injury Response System Based on a Robust Polymer Memristor to Mimic a Sense of Pain, Sign of Injury, and Healing." Advanced Science (2022): 2200629.

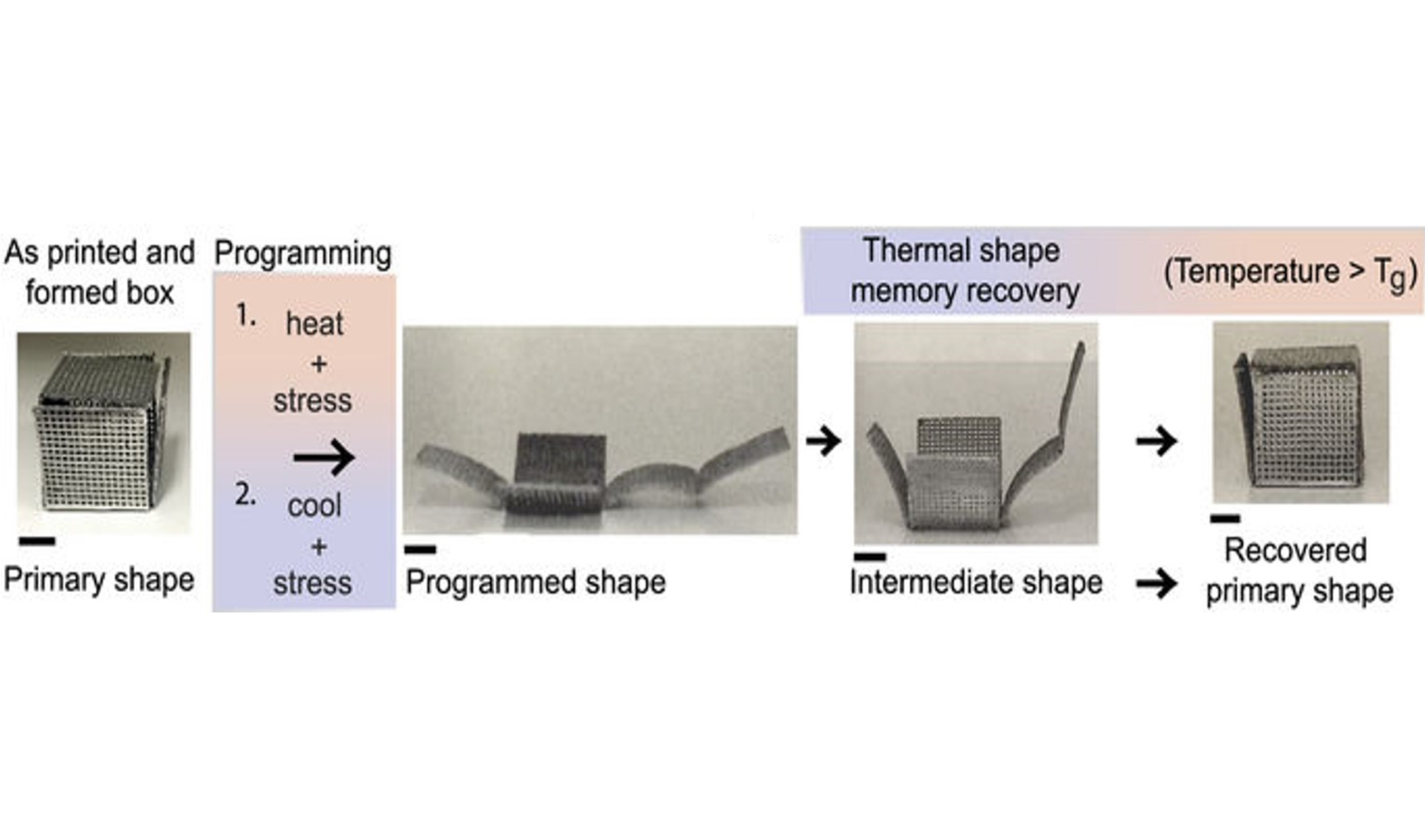

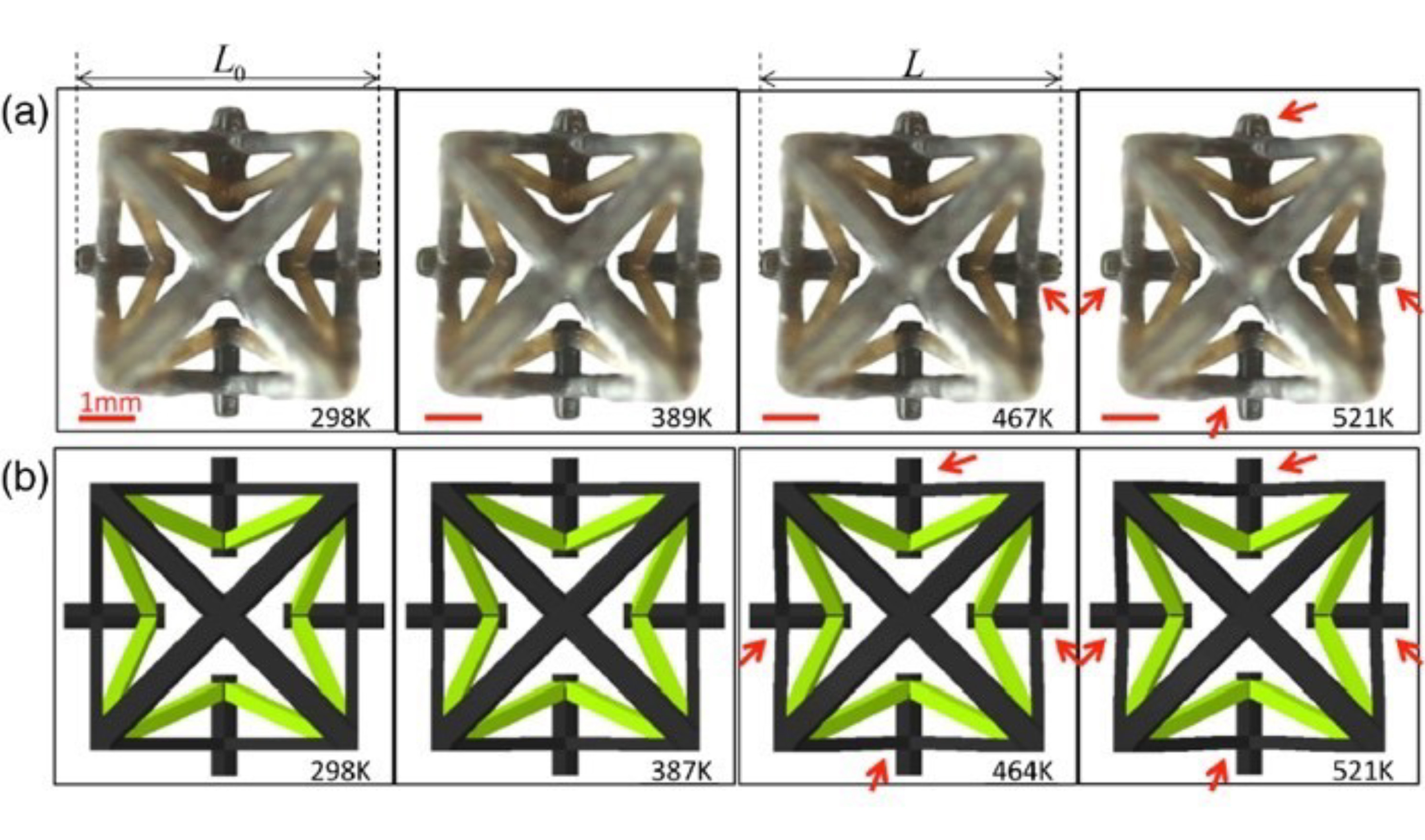

Deformable Materials

These printed materials deform under external stimuli like temperature, light, magnetism and radiation and return to their original state over time or under different conditions. Researchers can program the original and the deformed shape and use them to induce functional changes in a device. The materials are easy to process, lightweight and inexpensive compared to their metal counterparts and exhibit unique mechanical properties. Read more coverage

Deformable Materials

These printed materials deform under external stimuli like temperature, light, magnetism and radiation and return to their original state over time or under different conditions. Researchers can program the original and the deformed shape and use them to induce functional changes in a device. The materials are easy to process, lightweight and inexpensive compared to their metal counterparts and exhibit unique mechanical properties.

The materials were developed by CEMM’s Jennifer Rodriguez, Cheng Zhu, Eric Duoss, Thomas Wilson, Christopher Spadaccini and James Lewicki.

Relevant publication:

- Rodriguez, Jennifer N., et al. "Shape-morphing composites with designed micro-architectures." Scientific reports 6.1 (2016): 1-10.

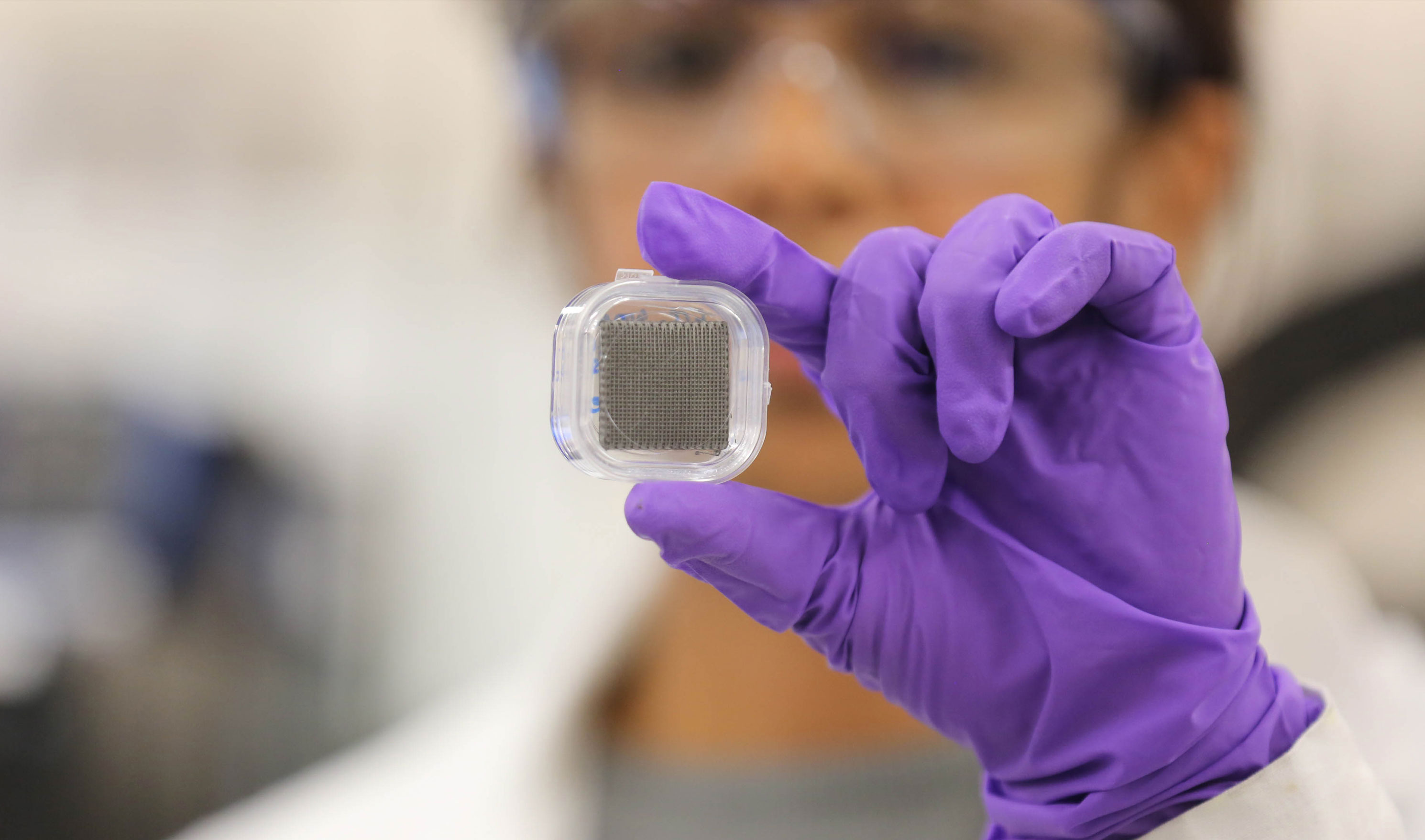

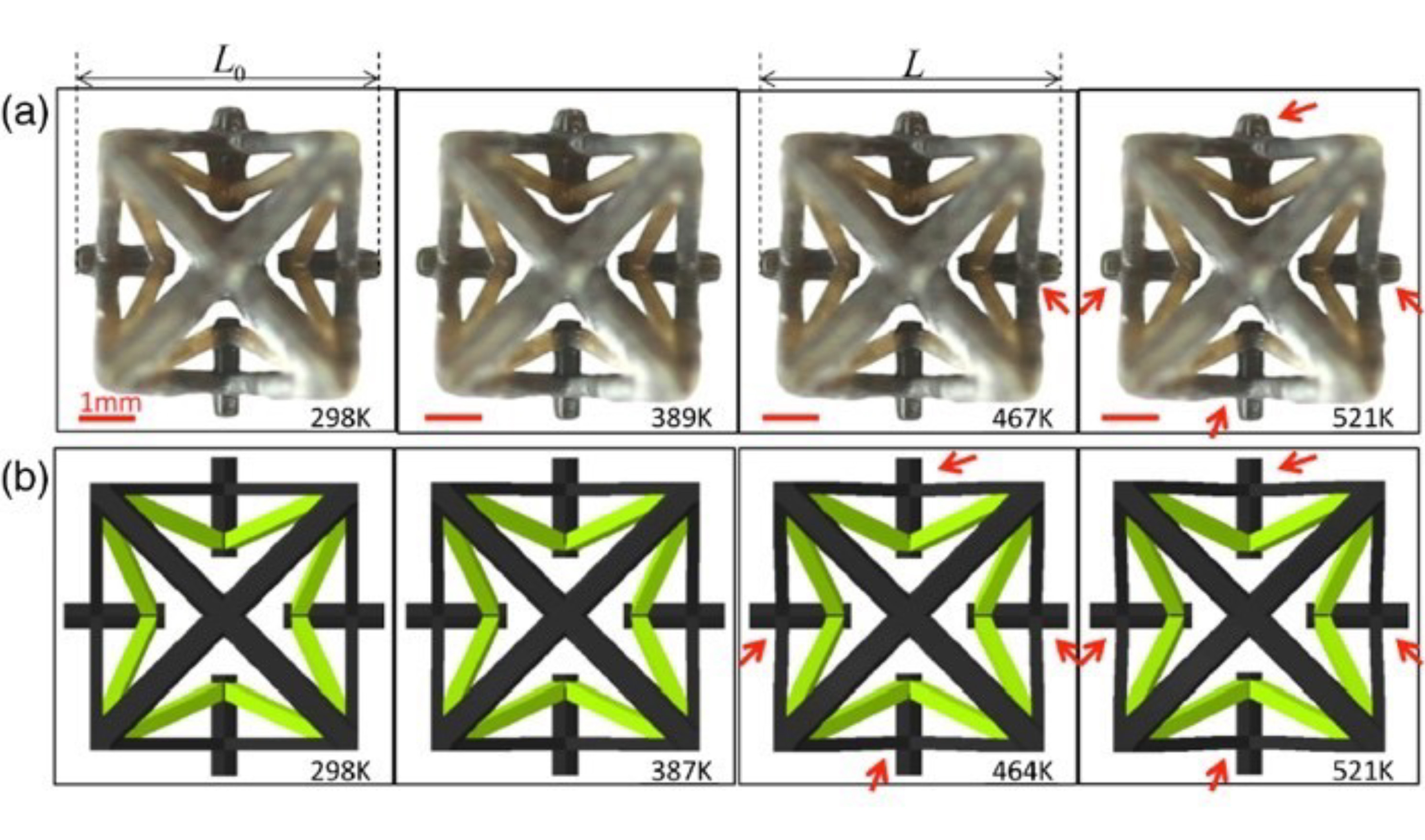

Multiscale Metallic Metamaterials

CEMM engineers have achieved unprecedented scalability in 3D-printed architectures of arbitrary geometry, opening the door to super-strong, ultra-lightweight and flexible metallic materials for the aerospace and automotive industries. Read more coverage

Multiscale Metallic Metamaterials

CEMM engineers have achieved unprecedented scalability in 3D-printed architectures of arbitrary geometry, opening the door to super-strong, ultra-lightweight and flexible metallic materials for the aerospace and automotive industries.

The materials have multiple layers of fractal-like lattices with features ranging from the nanometer to centimeter scale, resulting in a nickel-plated metamaterial with a high elasticity not found in any previously built metal foams or lattices.

The lattices were initially printed out of polymer, using a one-of-a-kind Large Area Projection Micro-Stereolithography (LAPuSL) printer invented at LLNL. The lattice structure was then coated with a nickel-phosphorus alloy and put through post-processing to remove the polymer core, leaving extremely lightweight, hollow tube structures.

Taking inspiration from the hierarchical structure of materials found in nature, such as wood and bone, the finished material incorporates multiple levels of feature size, from nanoscale films to the macroscale unit cells and lattices, within a single piece roughly five centimeters long. While testing the nickel-plated material, researchers found that structures fashioned with walls 700 nanometers thick broke under a 5 percent strain, while those with 60-nanometer walls stretched about 20 percent before failing.

Besides flexibility, researchers said the concept could overcome the current limitations of 3D-printed micro and nano-architectures by addressing the usual tradeoff between high resolution and build size and extend to a variety of large-scale applications, including aircraft parts, and batteries.

Read more:

Relevant publications:

Negative Thermal Expansion Materials

CEMM researchers helped develop a new class of metamaterials that are designed to contract instead of expand when exposed to heat. In addition, the materials can be "tuned" to shrink over a large range of temperatures by varying the thermal expansion coefficient difference between constituent beams and geometrical arrangements. Read more coverage

Negative Thermal Expansion Materials

CEMM researchers helped develop a new class of metamaterials that are designed to contract instead of expand when exposed to heat. In addition, the materials can be "tuned" to shrink over a large range of temperatures by varying the thermal expansion coefficient difference between constituent beams and geometrical arrangements.

The structure, printed from polymer and a polymer/copper composite material, can flex inward, causing the structure to contract when exposed to heat over a range of tens to hundreds of degrees—possibly the first experimental demonstration showing large tunability of negative thermal expansion (NTE) in three Cartesian directions of microlattice structures. The thermal expansion also can be zero or positive depending on how the geometry and topology of the structure are engineered.

Possible applications could come in securing parts that tend to move out of alignment under varying heat loads, including microchips and high precision optical mounts. The microstructured metamaterial could be used in dental fillings, which tend to move or crack when a person eats something hot, to fill in small gaps in bridges or buildings that are normally left open to account for thermal expansion, or in precision devices such as atomic-force microscopes.

Read more:

Relevant publication:

- Wang, Qiming, et al. "Lightweight mechanical metamaterials with tunable negative thermal expansion." Physical review letters 117.17 (2016): 175901.

Stiff Isotropic Lattices Beyond the Maxwell Criterion

CEMM researchers have looked beyond the conventional wisdom and designed stable microstructures using anisotropic lattices—mechanical trusses that are not equilibrium. Read more coverage

Stiff Isotropic Lattices Beyond the Maxwell Criterion

CEMM researchers have looked beyond the conventional wisdom and designed stable microstructures using anisotropic lattices—mechanical trusses that are not equilibrium. By superimposing complimentary anisotropic lattices, the center can create microstructures that rival their isotropic counterparts and open the door to new designs and materials with unprecedented properties.

Relevant publication:

- Chen, Wen, et al. "Stiff isotropic lattices beyond the Maxwell criterion." Science advances 5.9 (2019): eaaw1937.

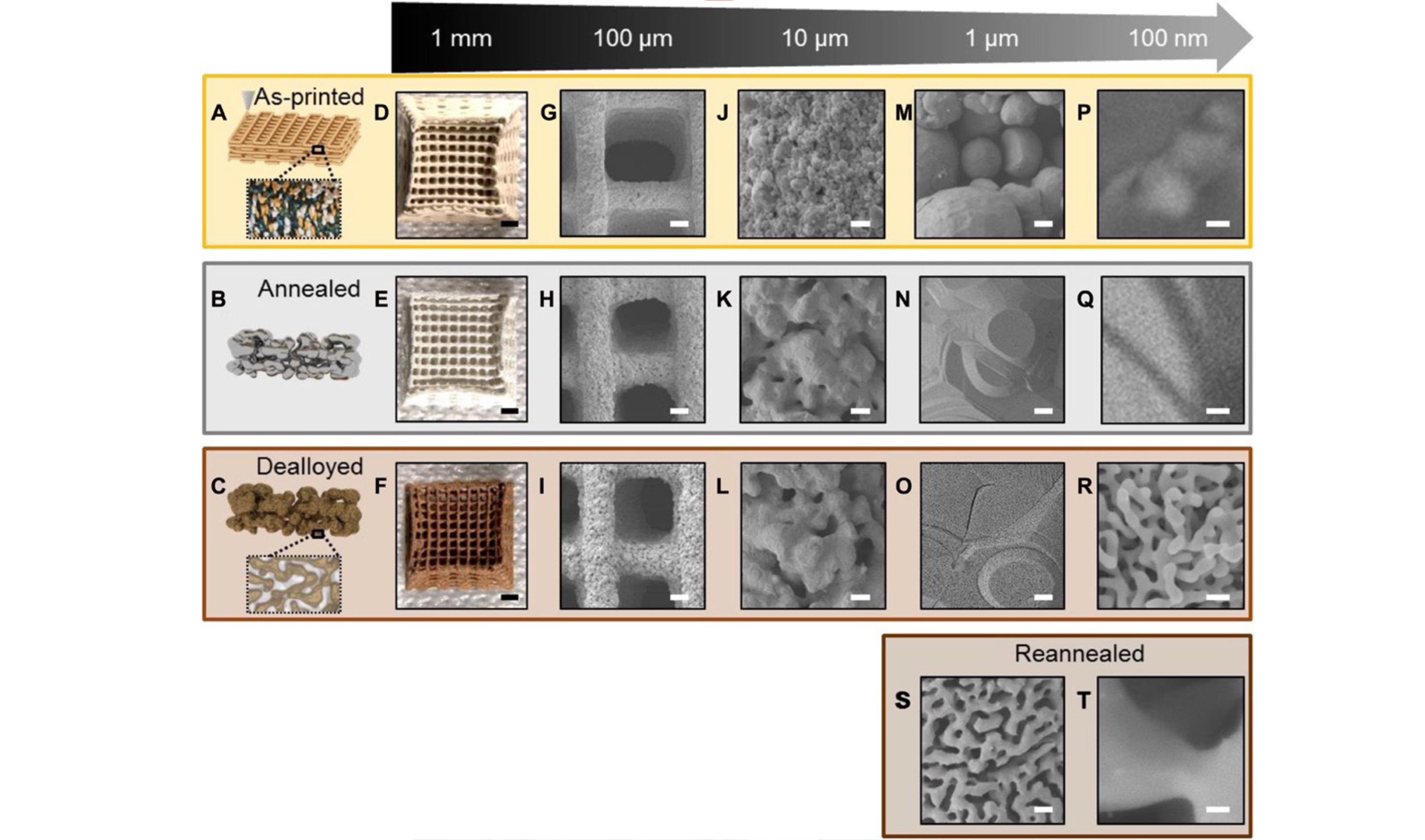

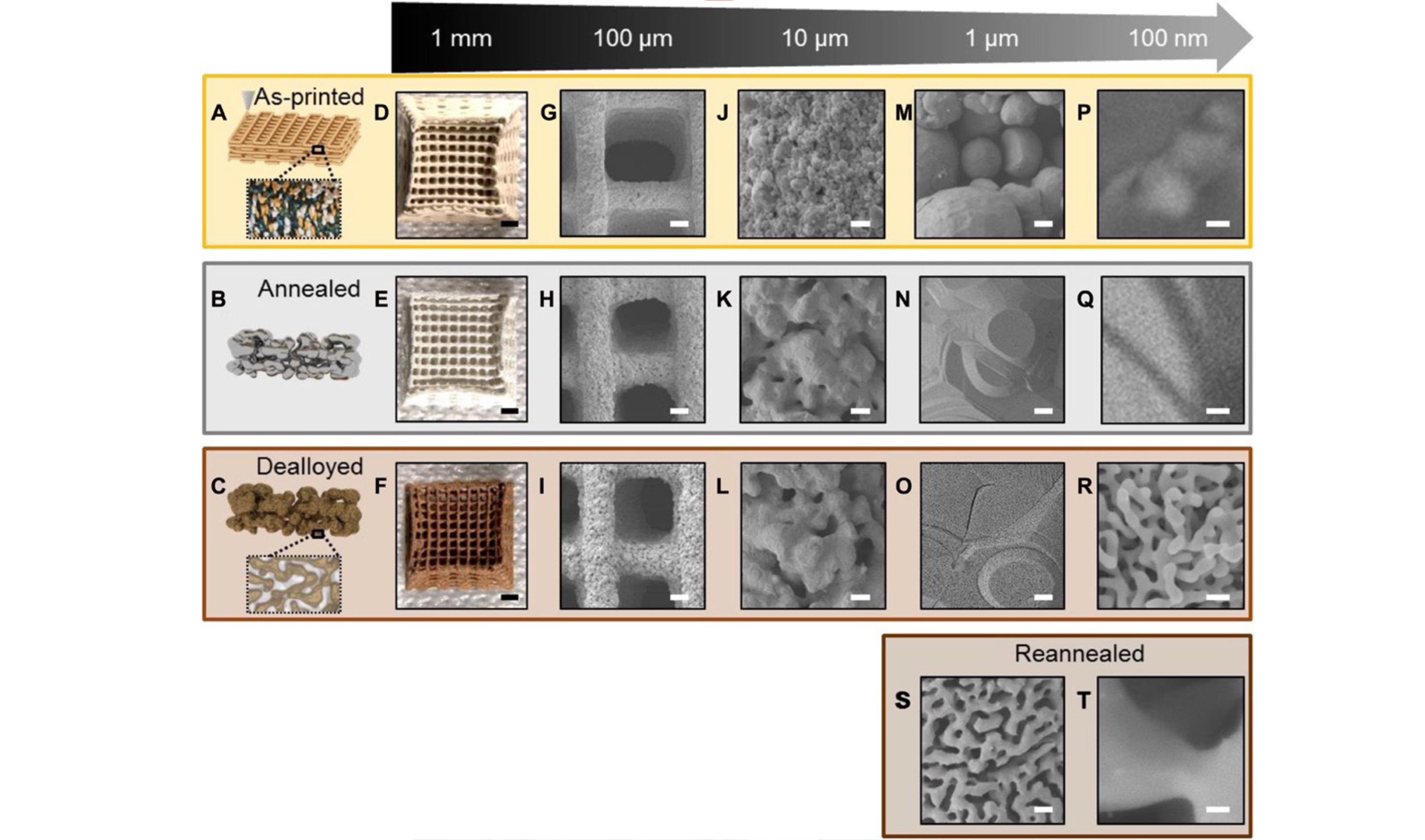

Hierarchically Nanoporous Materials

CEMM researchers were the first to additively manufacture nanoporous structures with controllable properties across scales. These materials have shown greatly improved mass transport and reaction rate for liquids and gases, and demonstrated the ability to control the integration of nanopores in the dealloying process. Read more coverage

Hierarchically Nanoporous Materials

CEMM researchers were the first to additively manufacture nanoporous structures with controllable properties across scales. These materials have shown greatly improved mass transport and reaction rate for liquids and gases, and demonstrated the ability to control the integration of nanopores in the dealloying process.

Relevant publication:

- Zhu, Cheng, et al. "Toward digitally controlled catalyst architectures: Hierarchical nanoporous gold via 3D printing." Science advances 4.8 (2018): eaas9459.

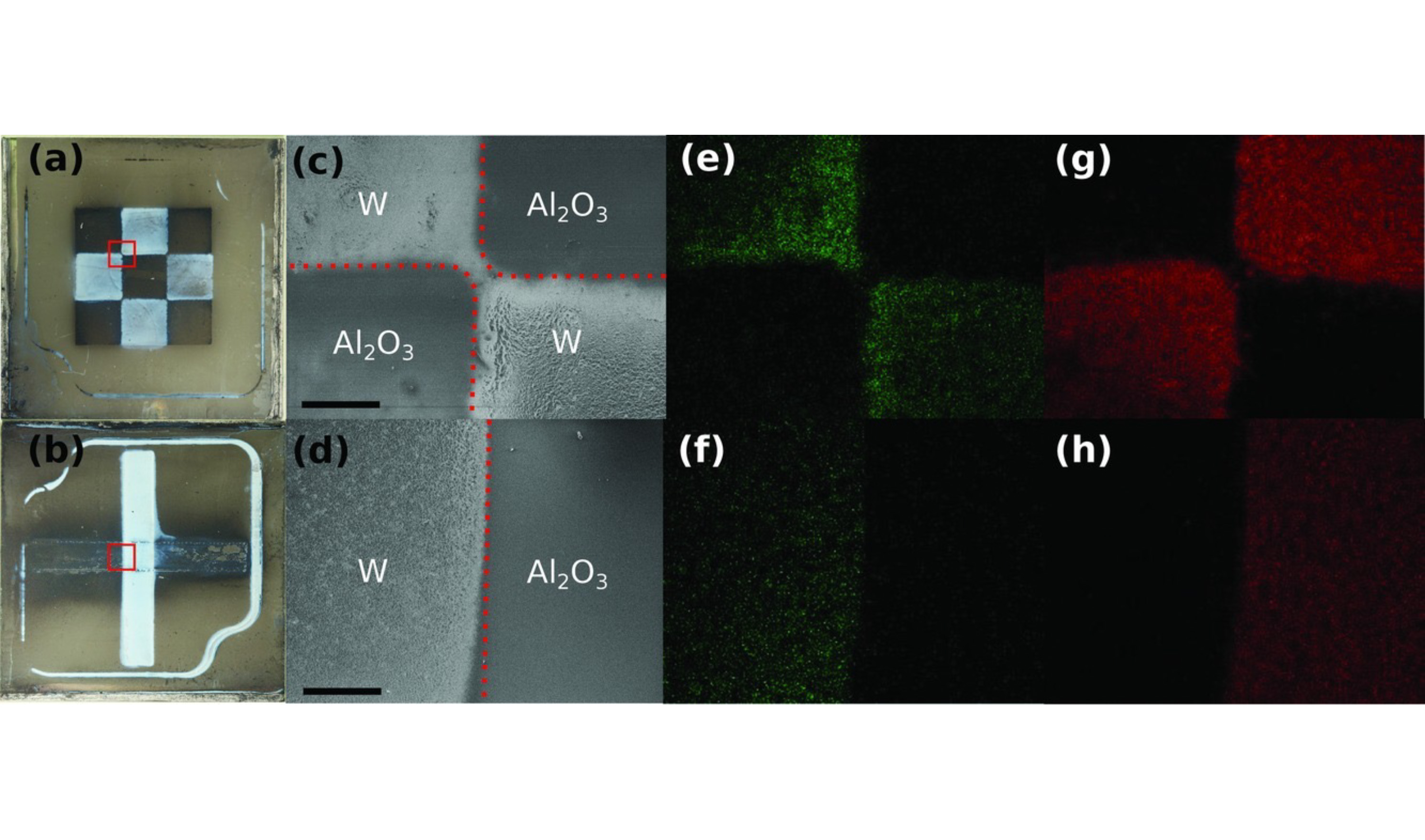

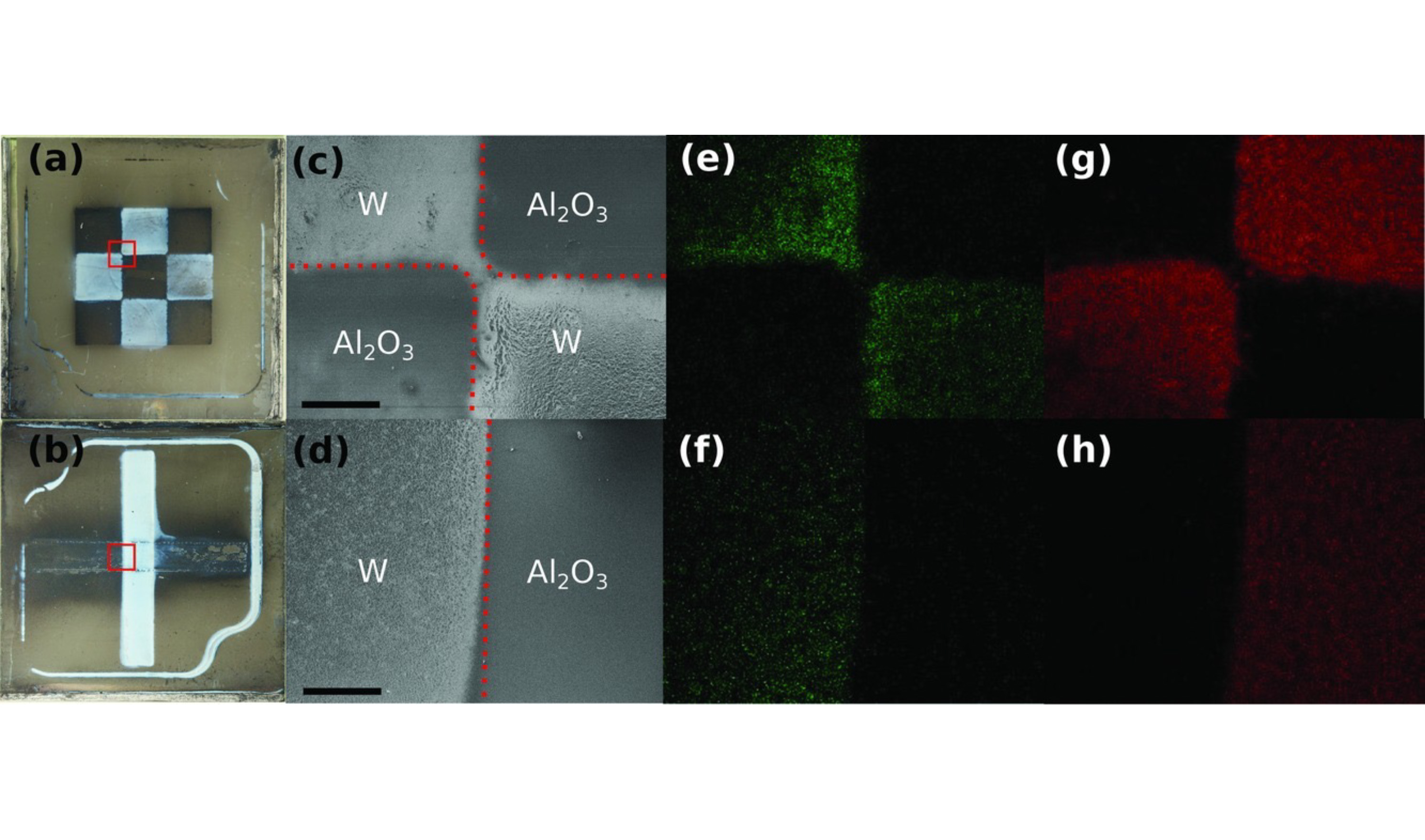

Spatial Control of Structure and Composition in Printed Multimaterials

CEMM researchers use a two-step curing process to spatially control the structure and composition of composite materials during printing. Read more coverage

Spatial Control of Structure and Composition in Printed Multimaterials

CEMM researchers use a two-step curing process to spatially control the structure and composition of composite materials during printing. Multiple materials can be printed within the same ink, but one is cured before the other to maximize stiffening and create new, previously unattainable structures with applications in soft robotics, functional materials and biomedical devices.

The innovative composite printing method combines electrophoretic deposition and light patterning to direct particles toward illuminated parts of the electrode. Since the electrode pattern can change throughout the print, it allows researchers to rapidly and precisely pattern multiple materials over a large area and produce a wide range of composites.

Relevant publications:

- Howell, Brian M., et al. "Spatially Controlled 3D Printing of Dual‐Curing Urethane Elastomers." Advanced Materials Technologies 7.3 (2022): 2100700.

- Pascall, Andrew J., et al. "Light‐Directed electrophoretic deposition: a new additive manufacturing technique for arbitrarily patterned 3D composites." Advanced Materials 26.14 (2014): 2252-2256.

Advancing Research

Despite its relative newness as a center, CEMM's groundbreaking work in additive manufacturing has produced materials with properties previously thought unfeasible or impractical. Our publication record speaks to the degree to which our team has pioneered the field and worked collaboratively with colleagues across academia, the national laboratory complex, and industry.

Xia, Xiaoxing, Christopher M. Spadaccini, and Julia R. Greer. "Responsive materials architected in space and time." Nature Reviews Materials (2022): 1-19.

Melchert, Drew S., et al. "Anisotropic Thermally Conductive Composites Enabled by Acoustophoresis and Stereolithography." Advanced Functional Materials (2022): 2201687.

Wang, Shanwen, et al. "Electrochemical Reduction of CO2 to Alcohols: Current Understanding, Progress, and Challenges." Advanced Energy and Sustainability Research 3.1 (2022): 2100131.

Lamaison, Sarah, et al. "Designing a Zn–Ag catalyst matrix and electrolyzer system for CO2 conversion to CO and beyond." Advanced Materials 34.1 (2022): 2103963.

Wakerley, David, et al. "Gas diffusion electrodes, reactor designs and key metrics of low-temperature CO2 electrolysers." Nature Energy 7.2 (2022): 130-143.

Howell, Brian M., et al. "Spatially Controlled 3D Printing of Dual‐Curing Urethane Elastomers." Advanced Materials Technologies 7.3 (2022): 2100700

Xu, Xiaojie, et al. "A Bioinspired Artificial Injury Response System Based on a Robust Polymer Memristor to Mimic a Sense of Pain, Sign of Injury, and Healing." Advanced Science (2022): 2200629

Rodriguez, Nicholas A., et al. "Use of wire grid polarizers with liquid crystal display for large-volume stereolithography." Additive Manufacturing 52 (2022): 102641.

Ford, Michael J., et al. "3D Printing of Transparent Silicone Elastomers." Advanced Materials Technologies 7.5 (2022): 2100974.

Lin, Yi‐Rung, et al. "Vapor‐Fed Electrolyzers for Carbon Dioxide Reduction Using Tandem Electrocatalysts: Cuprous Oxide Coupled with Nickel‐Coordinated Nitrogen‐Doped Carbon." Advanced Functional Materials (2022): 2113252.

Toombs, Joseph T., et al. "Volumetric additive manufacturing of silica glass with microscale computed axial lithography." Science 376.6590 (2022): 308-312.

Lin, Tiras Y., et al. "Topology optimization of 3D flow fields for flow batteries." Journal of The Electrochemical Society 169.5 (2022): 050540.

Karnes, John J., et al. "A Hybrid Quantum–Classical Study of Ion Adsorption at the Copper Electrode." The Journal of Physical Chemistry C (2022).

Loeb, Colin K., et al. "Hierarchical 3D Printed Porous Silicones with Porosity Derived from Printed Architecture and Silicone-Shell Microballoons." Additive Manufacturing 55 (2022): 102837.

Ford, Michael J., et al “3D Printing of Transparent Silicon Elastometers. Advanced Materials Technologies 7.5” (2022): 2100974

Sullivan, Ian, et al. "3D Printed Nickel–Molybdenum-Based Electrocatalysts for Hydrogen Evolution at Low Overpotentials in a Flow-Through Configuration." ACS Applied Materials & Interfaces 13.17 (2021): 20260-20268.

Melchert, Drew S., et al. "Modeling meso-and microstructure in materials patterned with acoustic focusing." Materials & Design 202 (2021): 109512.

Zhu, Yifan, et al. "Systematic Design and Experimental Demonstration of Transmission‐Type Multiplexed Acoustic Metaholograms." Advanced Functional Materials 31.27 (2021): 2101947.

Wicks, Joshua, et al. "3D‐Printable Fluoropolymer Gas Diffusion Layers for CO2 Electroreduction." Advanced Materials 33.7 (2021): 2003855.

Dudukovic, Nikola, et al. “Cellular fluidics.” Nature 595 (2021): 58-65.

Song, Hongtao, et al. "Development of a variable tensioning system to reduce separation force in large scale stereolithography." Additive Manufacturing 38 (2021): 101816.

Corral, Daniel, et al. "Advanced manufacturing for electrosynthesis of fuels and chemicals from CO 2." Energy & Environmental Science 14.5 (2021): 3064-3074.

Troksa, Alyssa L., et al. "3D-printed nanoporous ceramics: Tunable feedstock for direct ink write and projection microstereolithography." Materials & Design 198 (2021): 109337.

Chandrasekaran, Swetha, et al. "Carbon aerogels with integrated engineered macroporous architectures for improved mass transport." Carbon 179 (2021): 125-132.

Yao, Bin, et al. "Printing porous carbon aerogels for low temperature supercapacitors." Nano Letters 21.9 (2021): 3731-3737.

Peng, Siyuan, et al. "Additive manufacturing of three-dimensional (3D)-architected CoCrFeNiMn high-entropy alloy with great energy absorption." Scripta Materialia 190 (2021): 46-51.

Dubbin, Karen, et al. "Projection microstereolithographic microbial bioprinting for engineered biofilms." Nano Letters 21.3 (2021): 1352-1359.

Chang, Tammy, et al. "In-situ monitoring for liquid metal jetting using a millimeter-wave impedance diagnostic." Scientific reports 10.1 (2020): 1-9.

Yao, Bin, et al. "3D‐printed structure boosts the kinetics and intrinsic capacitance of pseudocapacitive graphene aerogels." Advanced Materials 32.8 (2020): 1906652.

Spadaccini, Christopher M. "Future perspectives on materials for two-photon polymerization." Three-Dimensional Microfabrication Using Two-Photon Polymerization. William Andrew Publishing, 2020. 671-681.

Wang, Shanwen, et al. "Cu2O/CuS nanocomposites show excellent selectivity and stability for formate generation via electrochemical reduction of carbon dioxide." ACS Materials Letters 3.1 (2020): 100-109.

Kou, Tianyi, et al. "Periodic Porous 3D Electrodes Mitigate Gas Bubble Traffic during Alkaline Water Electrolysis at High Current Densities." Advanced Energy Materials 10.46 (2020): 2002955.

Mooraj, Shahryar, et al. "3D printing of metal-based materials for renewable energy applications." Nano Research 14.7 (2021): 2105-2132.

Wang, Shanwen, et al. "Recent progress in electrochemical reduction of CO2 by oxide-derived copper catalysts." Materials Today Nano 12 (2020): 100096.

Wang, Jenny, et al. "Development of the Multi-Material Inspection for Closed-Loop Rapid Optimization (MICRO) Sensor for Extrusion-Based Additive Manufacturing of Metal-Polymer Composite Inks." IEEE Sensors Journal 21.1 (2020): 265-272.

Weitzner, Stephen E., et al. "Toward engineering of solution microenvironments for the CO2 reduction reaction: Unraveling pH and voltage effects from a combined density-functional–continuum theory." The Journal of Physical Chemistry Letters 11.10 (2020): 4113-4118.

Mooraj, Shahryar, et al. "Three-dimensional hierarchical nanoporous copper via direct ink writing and dealloying." Scripta Materialia 177 (2020): 146-150.

Bukosky, Scott C., et al. "Correlating dynamic microstructure to observed color in electrophoretic displays via in situ small-angle x-ray scattering." Physical Review Materials 4.7 (2020): 075802.

Elton, Eric S., et al. "Dramatic effect of oxide on measured liquid metal rheology." Journal of Rheology 64.1 (2020): 119-128.

Chandrasekaran, Swetha, et al. "Additive manufacturing of graded B4C-Al cermets with complex shapes." Materials & Design 188 (2020): 108516.

Cook, Caitlyn, et al. “Additive Manufacturing: Highly Tunable Thiol-Ene Photoresins for Volumetric Additive Manufacturing.” Advanced Materials 32.47 (2020): 2003376.

Dylla-Spears, Rebecca, et al. "3D printed gradient index glass optics." Science advances 6.47 (2020): eabc7429.

Sasan, Koroush, et al. "Additive manufacturing of optical quality germania–silica glasses." ACS applied materials & interfaces 12.5 (2020): 6736-6741.

Beck, Victor A., et al. "A combined numerical and experimental study to elucidate primary breakup dynamics in liquid metal droplet-on-demand printing." Physics of Fluids 32.11 (2020): 112020.

Lee, Xian Yeow, et al. "Automated detection of part quality during two-photon lithography via deep learning." Additive Manufacturing 36 (2020): 101444.

Gaikwad, Aniruddha, et al. "Heterogeneous sensing and scientific machine learning for quality assurance in laser powder bed fusion–a single-track study." Additive Manufacturing 36 (2020): 101659.

Karnes, John J., et al. "On the network topology of cross-linked acrylate photopolymers: a molecular dynamics case study." The Journal of Physical Chemistry B 124.41 (2020): 9204-9215.

Qian, Fang, et al. “Direct Writing of Tunable Living Inks for Bioprocess Intensification.” Nano Letters 19.9 (2019): 5829–5835

Spadaccini, Christopher M. "Ultrastrong, Ductile Ceramic Lattices Span an Order of Magnitude in Size." Matter 1.6 (2019): 1445-1446.

Spadaccini, Christopher. "Additive manufacturing and architected materials: New process developments and materials." The Journal of the Acoustical Society of America 146.4 (2019): 2756-2756.

Spadaccini, Christopher M. "Additive manufacturing and processing of architected materials." MRS Bulletin 44.10 (2019): 782-788.

Chen, Wen, et al. "Microscale residual stresses in additively manufactured stainless steel." Nature communications 10.1 (2019): 1-12.

Chen, Wen, et al. "Stiff isotropic lattices beyond the Maxwell criterion." Science advances 5.9 (2019): eaaw1937.

Golobic, Alexandra M., et al. "Active mixing of reactive materials for 3D printing." Advanced Engineering Materials 21.8 (2019): 1900147.

Morris, Clinton, et al. "Tunable Mechanical Metamaterial with Constrained Negative Stiffness for Improved Quasi‐Static and Dynamic Energy Dissipation." Advanced Engineering Materials 21.7 (2019): 1900163.

Zhu, Cheng, et al. "Colloidal materials for 3D printing." Annual review of chemical and biomolecular engineering 10 (2019): 17-42.

Kelly, Brett E., et al. "Volumetric additive manufacturing via tomographic reconstruction." Science 363.6431 (2019): 1075-1079.

Yao, Bin, et al. "Efficient 3D printed pseudocapacitive electrodes with ultrahigh MnO2 loading." Joule 3.2 (2019): 459-470.

Trembacki, Bradley, et al. "Mesoscale electrochemical performance simulation of 3d interpenetrating lithium-ion battery electrodes." Journal of the Electrochemical Society 166.6 (2019): A923.

Trembacki, Bradley, et al. "Mesoscale electrochemical performance simulation of 3D interpenetrating lithium-ion battery electrodes." Journal of the Electrochemical Society 166.6 (2019): A923.

Nguyen, Du T., et al. "3D printing of compositional gradients using the microfluidic circuit analogy." Advanced Materials Technologies 4.12 (2019): 1900784.

Karnes, John J., Nathan Villavicencio, and Ilan Benjamin. "Transfer of an erbium ion across the water/dodecane interface: Structure and thermodynamics via molecular dynamics simulations." Chemical Physics Letters 737 (2019): 136825.

Saha, Sourabh K., et al. "Scalable submicrometer additive manufacturing." Science 366.6461 (2019): 105-109.

Roehling, John D., et al. "Reducing residual stress by selective large-area diode surface heating during laser powder bed fusion additive manufacturing." Additive Manufacturing 28 (2019): 228-235.

Chu, Albert, et al. "Automated detection and sorting of microencapsulation via machine learning." Lab on a Chip 19.10 (2019): 1808-1817.

Song, Yuanping, et al. "Additively manufacturable micro-mechanical logic gates." Nature communications 10.1 (2019): 1-6.

Jackson, Julie A., et al. "Field responsive mechanical metamaterials." Science advances 4.12 (2018): eaau6419.

Zhu, Cheng, et al. "Toward digitally controlled catalyst architectures: Hierarchical nanoporous gold via 3D printing." Science advances 4.8 (2018): eaas9459.

Nygren, Richard E., et al. "Advanced manufacturing—A transformative enabling capability for fusion." Fusion Engineering and Design 136 (2018): 1007-1011.

Valdevit, Lorenzo, et al. "Architected materials: synthesis, characterization, modeling, and optimal design." Journal of Materials Research 33.3 (2018): 241-246.

Bishop-Moser, Josh, Christine Andres, and Chris Spadaccini. "A Call to Action: Manufacturing Architected Materials." (2018): 247-248.

Qi, Zhen, et al. "3D-Printed, Superelastic Polypyrrole–Graphene Electrodes with Ultrahigh Areal Capacitance for Electrochemical Energy Storage." Advanced Materials Technologies 3.7 (2018): 1800053.

Weisgraber, Todd H., et al. "A mechanical reduced order model for elastomeric 3D printed architectures." Journal of Materials Research 33.3 (2018): 309-316.

Bishop-Moser, Josh, Chris Spadaccini, and Christine Andres. Metamaterials manufacturing: Pathway to industrial competitiveness. 2018.

Chandrasekaran, Swetha, et al. "Direct ink writing of organic and carbon aerogels." Materials Horizons 5.6 (2018): 1166-1175.

Hensleigh, Ryan M., et al. "Additive manufacturing of complex micro-architected graphene aerogels." Materials Horizons 5.6 (2018): 1035-1041.

Song, Yu, et al. "Three-dimensional carbon architectures for electrochemical capacitors." Journal of colloid and interface science 509 (2018): 529-545.

Jones, Ivy Krystal, et al. "Direct ink write fabrication of transparent ceramic gain media." Optical Materials 75 (2018): 19-25.

Durban, Matthew M., et al. "Custom 3D printable silicones with tunable stiffness." Macromolecular Rapid Communications 39.4 (2018): 1700563.

Weisgraber, Todd H., et al. "A mechanical reduced order model for elastomeric 3D printed architectures." Journal of Materials Research 33.3 (2018): 309-316.

Destino, Joel F., et al. "3D printed optical quality silica and silica–titania glasses from sol–gel feedstocks." Advanced Materials Technologies 3.6 (2018): 1700323.

Dudukovic, Nikola A., et al. "Predicting nanoparticle suspension viscoelasticity for multimaterial 3D printing of silica–titania glass." ACS Applied Nano Materials 1.8 (2018): 4038-4044.

Lu, Ryan, et al. "Complex shaped boron carbides from negative additive manufacturing." Materials & Design 148 (2018): 8-16.

Mora, Jeronimo, et al. "Projection based light-directed electrophoretic deposition for additive manufacturing." Additive Manufacturing 22 (2018): 330-333.

Lu, Ryan, et al. "Negative additive manufacturing of complex shaped boron carbides." JoVE (Journal of Visualized Experiments) 139 (2018): e58438.

Qian, Fang, et al. “Ultralight Conductive Silver Nanowire Aerogels. Nano Letters 17.12 (2017): 7171-7176

Shusteff, Maxim, et al. "One-step volumetric additive manufacturing of complex polymer structures." Science advances 3.12 (2017): eaao5496.

Shaw, L. A., et al. "Scanning holographic optical tweezers." Optics Letters 42.15 (2017): 2862-2865.

Zhu, Cheng, et al. "3D printed functional nanomaterials for electrochemical energy storage." Nano Today 15 (2017): 107-120.

Kelly, Brett, et al. "Computed axial lithography (CAL): Toward single step 3D printing of arbitrary geometries." arXiv preprint arXiv:1705.05893 (2017).

Leon, Juan J. Diaz, et al. “Design Rules for Tailoring Antireflection Properties of Hierarchical Optical Structure.” Advanced Optical Materials 5.13 (2017): 1700080.

Matthews, Manyalibo J., et al. "Diode-based additive manufacturing of metals using an optically-addressable light valve." Optics express 25.10 (2017): 11788-11800.

Chen, Wen, et al. "Direct metal writing: Controlling the rheology through microstructure." Applied Physics Letters 110.9 (2017): 094104.

Lewicki, James P., et al. "3D-printing of meso-structurally ordered carbon fiber/polymer composites with unprecedented orthotropic physical properties." Scientific reports 7.1 (2017): 1-14.

“Tunable Amorphous Photonic Materials with Pigmentary Colloidal Nanostructures” – Han et al (2017)

Wu, Amanda S., et al. "3D printed silicones with shape memory." Scientific reports 7.1 (2017): 1-6.

Nguyen, Du T., et al. "3D‐printed transparent glass." Advanced Materials 29.26 (2017): 1701181.

C. Zhu, et al., “Controlling Material Reactivity Using Architecture.” Advanced Materials 28 (2016): 1934-1939.Wang, Qiming, et al. "Lightweight mechanical metamaterials with tunable negative thermal expansion." Physical review letters 117.17 (2016): 175901.

Stolaroff, Joshuah K., et al. "Microencapsulation of advanced solvents for carbon capture." Faraday discussions 192 (2016): 271-281.

Zheng, Xiaoyu, et al. "Multiscale metallic metamaterials." Nature materials 15.10 (2016): 1100-1106.

Hopkins, Jonathan B., et al. "Design of nonperiodic microarchitectured materials that achieve graded thermal expansions." Journal of Mechanisms and Robotics 8.5 (2016): 051010.

Shaw, L. A., et al. "Holographic optical assembly and photopolymerized joining of planar microspheres." Optics letters 41.15 (2016): 3571-3574.

Liu, Tianyu, et al. "Ion Intercalation Induced Capacitance Improvement for Graphene‐Based Supercapacitor Electrodes." ChemNanoMat 2.7 (2016): 635-641.

Smith, William, et al. “Multiscale metallic metamaterials.” Nature Materials 15 (2016): 1100-1106

Qian, Fang, et al. “Multiphase separation of copper nanowires.” Chemical Communications 78 (2016): 11627-11630

Rodriguez, Jennifer N., et al. "Shape-morphing composites with designed micro-architectures." Scientific reports 6.1 (2016): 1-10.

Zhu, Cheng, et al. "Supercapacitors based on three-dimensional hierarchical graphene aerogels with periodic macropores." Nano letters 16.6 (2016): 3448-3456.

Maiti, A., et al. "3D printed cellular solid outperforms traditional stochastic foam in long-term mechanical response." Scientific reports 6.1 (2016): 1-9.

Hopkins, Jonathan B., et al. "Polytope sector-based synthesis and analysis of microstructural architectures with tunable thermal conductivity and expansion." Journal of Mechanical Design 138.5 (2016): 051401.

Sullivan, Kyle T., et al. "Controlling material reactivity using architecture." Advanced Materials 28.10 (2016): 1934-1939.

Jones, Ivy Krystal, et al. "Functionally Graded Solid-State Laser Gain Media Fabricated by Direct Ink Write and Ceramic Processing." Advanced Solid State Lasers. Optical Society of America, 2016.

Giera, Brian, et al. "Mesoscale particle-based model of electrophoresis." Journal of The Electrochemical Society 162.11 (2015): D3030.

Zhu, Cheng, et al. "Highly compressible 3D periodic graphene microlattices." Nature communications 6.1 (2015): 1-8.

Vericella, John J., et al. "Encapsulated liquid sorbents for carbon dioxide capture." Nature Communications 6.1 (2015): 1-7.

Qian, Fang, et al. "On-demand and location selective particle assembly via electrophoretic deposition for fabricating structures with particle-to-particle precision." Langmuir 31.12 (2015): 3563-3568.

Giera, Brian, et al. "Mesoscale particle-based model of electrophoresis." Journal of The Electrochemical Society 162.11 (2015): D3030.

Duoss, Eric B., et al. "Three‐dimensional printing of elastomeric, cellular architectures with negative stiffness." Advanced Functional Materials 24.31 (2014): 4905-4913

Zheng, Xiaoyu, et al. "Ultralight, ultrastiff mechanical metamaterials." Science 344.6190 (2014): 1373-1377.

Pascall, Andrew J., et al. "Light‐Directed electrophoretic deposition: a new additive manufacturing technique for arbitrarily patterned 3D composites." Advanced Materials 26.14 (2014): 2252-2256.

Sullivan, K. T., et al. "Electrophoretic deposition of thermites onto micro-engineered electrodes prepared by direct-ink writing." The Journal of Physical Chemistry B 117.6 (2013): 1686-1693.

Hopkins, Jonathan B., Kyle J. Lange, and Christopher M. Spadaccini. "Designing microstructural architectures with thermally actuated properties using freedom, actuation, and constraint topologies." Journal of Mechanical Design 135.6 (2013): 061004.

Zheng, Xiaoyu, et al. "Design and optimization of a light-emitting diode projection micro-stereolithography three-dimensional manufacturing system." Review of Scientific Instruments 83.12 (2012): 125001.

Suss, Matthew E., et al. "Capacitive desalination with flow-through electrodes." Energy & Environmental Science 5.11 (2012): 9511-9519.

Lorang, David J., et al. "Photocurable liquid core–fugitive shell printing of optical waveguides." Advanced Materials 23.43 (2011): 5055-5058.

Collaborate with Us

Let’s make something incredible together

We’d love to explore what a collaboration with your organization might involve. Fill out the form below to get started.

Please don't edit this area