Computational Engineering

Modeling for Prediction and Insight

Modeling, simulation, and data science are collaborative endeavors with participation across the Engineering divisions—in particular the Computational Engineering Division, the National Security Engineering Division, and the Defense Technologies Engineering Division. Collectively, our teams advance modeling and simulation, data-analytic tools, and entire fields of study, such as collaborative autonomy—all with the aid of LLNL’s massive computing facilities.

Our goal is to create and utilize computational models to provide insights into physical systems for the Laboratory and its sponsors. Given the breadth of R&D concerns at LLNL, Engineering relies upon a broad portfolio of software tools to generate and execute these models. A key set of capabilities for modeling hydro-structural response, fluid flow, and electromagnetics are internally developed to meet our specialized needs and provide rapid support to users. Other modeling needs are best met by using commercially available software, for which we also have expert users.

Other modeling needs are met through data science techniques. Vast data sets, whether gathered by physical observations or simulations, can now be computationally digested to generate models revealing essential relationships within the data. These models can also support prediction of scenarios not already observed. In the emerging field of collaborative autonomy, data-analytic techniques are used both to distill the best aggregate measurements from a collection of mobile sensor platforms and to collectively decide how to reposition themselves to achieve improved measurements.

Computational engineering at LLNL flourishes through the broad array of computing platforms available. LLNL’s High Performance Computing (HPC) facility houses several of the Top 500 most powerful computers worldwide, and in 2023 will include one of the world’s first exascale computing platforms. These platforms are supported by an entire ecosystem, including visualization platforms, storage arrays, and high-bandwidth networks. At other times, specialized hardware such as FPGAs (field programmable gate arrays) is utilized when best positioned to meet the performance needs of a particular application.

Please do not alter or edit this area. This generates the skewed image boxes.

border-box-0

border-box-1

border-box-2

Project Highlights

From computer simulations to compact algorithms, we harness LLNL’s high-performance computing capabilities to address issues of national security and to solve problems with global impact.

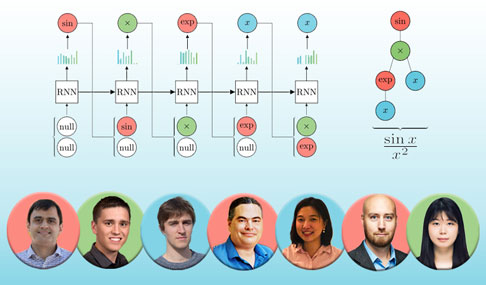

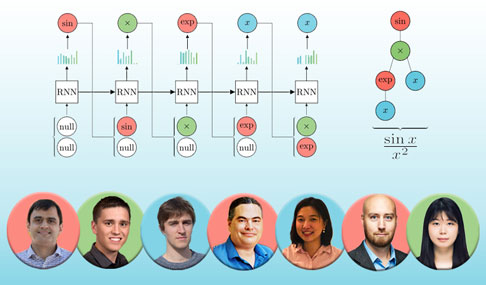

Applying Deep Reinforcement Learning to Symbolic Regression Problems

In a paper from March 2021, LLNL computer scientists explained a new framework and an accompanying visualization tool that leverages deep reinforcement learning for symbolic regression problems. Read Full Article

Applying Deep Reinforcement Learning to Symbolic Regression Problems

In a paper from March 2021, LLNL computer scientists explained a new framework and an accompanying visualization tool that leverages deep reinforcement learning for symbolic regression problems—problems that deal with discrete “building blocks” which must be combined in a particular order or configuration to optimize a desired property. The team focused on a type of discrete optimization called symbolic regression—finding compact mathematical expressions that fit data gathered from an experiment. Symbolic regression aims to uncover the underlying equations or dynamics of a physical process.

Symbolic regression is typically approached in machine learning and artificial intelligence with evolutionary algorithms, explained lead author Brenden Petersen. The problem with evolutionary approaches is that the algorithms aren’t principled and don’t scale very well, he explained.

Co-author Mikel Landajuela notes that, “At the core of our approach is a neural network that is learning the landscape of discrete objects; it holds a memory of the process and builds an understanding of how these objects are distributed in this massive space to determine a good direction to follow. That’s what makes our algorithm work better — the combination of memory and direction are missing from traditional approaches.”

The team has been testing it on real-world physics problems such as thin-film compression, where it is showing promising results. Authors said the algorithm is widely applicable not just to symbolic regression, but to any kind of discrete optimization problem. They have recently started to apply it to the creation of unique amino acid sequences for improved binding to pathogens for vaccine design.

Other Project Highlights

New Computer Simulations Reveal New Information about High Explosives

Engineers in the Computational Engineering Division unveiled computer simulations exploring the effects of shock waves on crystalline HMX in the May 2015 issue of the Journal of Applied Physics. Read Full Article

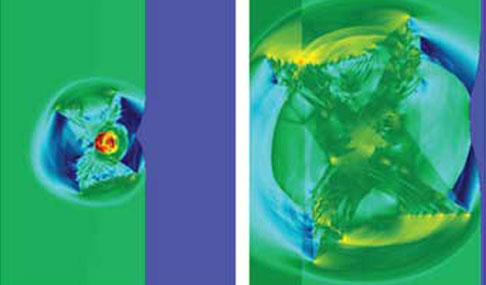

New Computer Simulations Reveal New Information about High Explosives

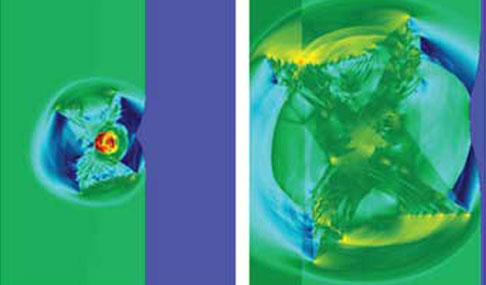

Engineers in the Computational Engineering Division unveiled computer simulations exploring the effects of shock waves on crystalline HMX in the May 2015 issue of the Journal of Applied Physics.

The work is part of a broader research project to better understand the safety and performance of high explosives that are used in the nuclear stockpile. "We want to better understand why some explosives are safe and others are less safe," said Larry Fried, Reaction Dynamics group leader in Physical and Life Sciences.

HMX crystals contain defects in the form of pores or bubbles. When shocked, the pores collapse and form "hot spots," which in turn, can produce small burning regions that propagate in a self-sustained manner. The interaction of burn/pressure fronts from many hot spots is what causes the build-up to detonation. However, scientists still didn’t precisely understand how the burning reactions are initiated which lead to detonation.

Employing state-of-the-art material models that allowed the simulations to elucidate most of the physical processes involved is a significant step towards comprehending the physics of the hot spots. A significant finding of the simulations was prominent shear banding (melt cracking) around a collapsing pore—an effect derived from the strength response of the crystal. This behavior is in stark contrast to predictions from conventional strength models, which typically do not account for the anisotropic, viscoplastic nature of crystal deformation. The simulations show that reactions can be initiated within the shear bands (extended hot spots) on a nanosecond (billionth of a second) time scale.

Other Project Highlights

LLNL GUIDE Rapid Response Platform Employed by DOD in Omicron Response

Between 2020 and 2022, engineers at LLNL used machine learning to create antibodies against Omicron, which has had immediate clinical interest and investment. .Read Full Article

LLNL GUIDE Rapid Response Platform Employed by DOD in Omicron Response

Between 2020 and 2022, engineers at LLNL used machine learning to create antibodies against Omicron, which has had immediate clinical interest and investment.

Led by Dan Faissol and Tom Desautels of the Computational Engineering Division, the work has made use of LLNL’s largest supercomputer, Sierra, to advance very quickly in the face of the 2021-2022 Omicron variant of COVID-19. Named “GUIDE,” the project is an AI-enabled, rapid biologic countermeasure design consortium, led by LLNL and with input from Los Alamos and Sandia National Labs, plus representatives from industry and academia.

GUIDE was initiated when primary antibody therapy CoV-2130 proved ineffective against Omicron, requiring re-targeting of this antibody product. Within just two and a half weeks, the LLNL team provided ~200 antibody sequences predicted to be effective and manufacturable (and which were under testing as of March 2022). This was done via an extensive campaign that used over 1 million GPU hours, including first use of Sierra in non-defense application.

The team drew upon expertise at LLNL in biology, high-performance computing, and machine learning to create possible countermeasures for COVID-19 and to prepare for future outbreaks.

Other Project Highlights

Related Facilities and Centers

Advanced Manufacturing Laboratory

The Advanced Manufacturing Laboratory (AML) is part of the Livermore Valley Open Campus (LVOC)—a 110-acre open and unclassified innovation hub for stimulating collaborative projects with external partners in government, industry, and academia. LVOC is a joint initiative of the NNSA, LLNL, and Sandia National Laboratories.

Advanced Manufacturing Laboratory

The Advanced Manufacturing Laboratory (AML) is part of the Livermore Valley Open Campus (LVOC)—a 110-acre open and unclassified innovation hub for stimulating collaborative projects with external partners in government, industry, and academia. LVOC is a joint initiative of the NNSA, LLNL, and Sandia National Laboratories.

Center for Advanced Signal and Image Sciences

The Center for Advanced Signal and Image Sciences (CASIS) establishes a forum where research scientists and engineers can freely exchange information and ideas, focused on the areas of the signal and image sciences.

Center for Advanced Signal and Image Sciences

The Center for Advanced Signal and Image Sciences (CASIS) establishes a forum where research scientists and engineers can freely exchange information and ideas, focused on the areas of the signal and image sciences.

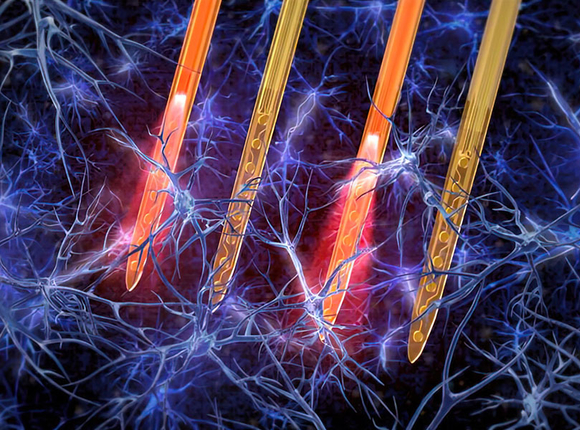

The Center for Bioengineering applies its tools and principles to complex, biological systems. Our mission challenge is to enable transformational solutions to counter biological threats and increase national resilience.

The Center for Bioengineering applies its tools and principles to complex, biological systems. Our mission challenge is to enable transformational solutions to counter biological threats and increase national resilience.

Center for Engineered Materials and Manufacturing

The Center for Engineered Materials and Manufacturing (CEMM) spans multiple laboratories, innovating additive manufacturing techniques to create structural and functional materials with novel capabilities. The center also serves as an incubator, training future additive manufacturing talents.

Center for Engineered Materials and Manufacturing

The Center for Engineered Materials and Manufacturing (CEMM) spans multiple laboratories, innovating additive manufacturing techniques to create structural and functional materials with novel capabilities. The center also serves as an incubator, training future additive manufacturing talents.

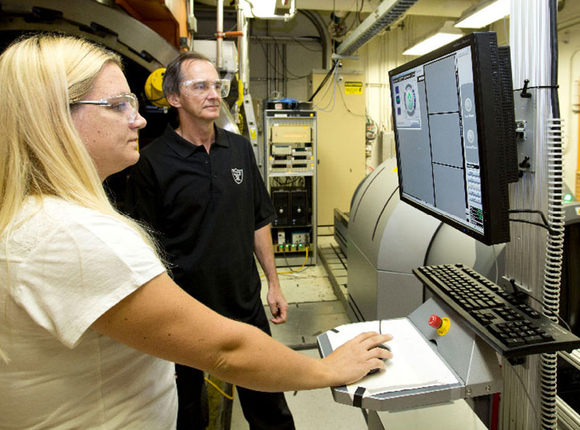

Nondestructive Characterization Institute

Nondestructive characterization aims to understand the internal physical properties of a material, component, or system without causing damage. The Nondestructive Characterization Institute advances the fields of non-destructive evaluation and characterization through collaborative research and development applied to real-world national security problems.

Nondestructive Characterization Institute

Nondestructive characterization aims to understand the internal physical properties of a material, component, or system without causing damage. The Nondestructive Characterization Institute advances the fields of non-destructive evaluation and characterization through collaborative research and development applied to real-world national security problems.

Take Your Place on the

Leading Edge

Our work is fundamentally transforming the field of advanced manufacturing and materials engineering. Learn more about what a career with LLNL Engineering might have in store for you.