Systems Engineering at LLNL

Contextualizing Decisions and Technologies

Our systems engineering covers many areas, from sensor development to space science engineering. Using advanced modeling tools plus optimization capabilities and uncertainty quantification, systems engineering strives to quantify and elucidate decision-making and to hone new technologies within the context of the systems they will impact.

Systems engineering at LLNL works in collaboration with other national laboratories, production agencies, and the Department of Defense to survey the active stockpile to assess safety, reliability, and performance and to create simulation tools and execute tests to modernize the stockpile of the future.

In addition to weapons systems engineering, this area runs the gamut from planetary exploration to high altitude sensors to studying greenhouse gases to space defense—LLNL Engineering is at the forefront of the final frontier.

Please do not alter or edit this area. This generates the skewed image boxes.

border-box-0

border-box-1

border-box-2

Project Highlights

Systems engineering offers a range of manufacturing capabilities and precision and materials-engineering technologies in support of national like homeland security, space science and security, and stockpile stewardship.

Updating Nuclear Warheads

In late 2020, LLNL engineers and researchers accomplished their first key program level achievement in the W87-1 Modification Program, which will replace the W78 thermonuclear warhead. Read Full Article

Updating Nuclear Warheads

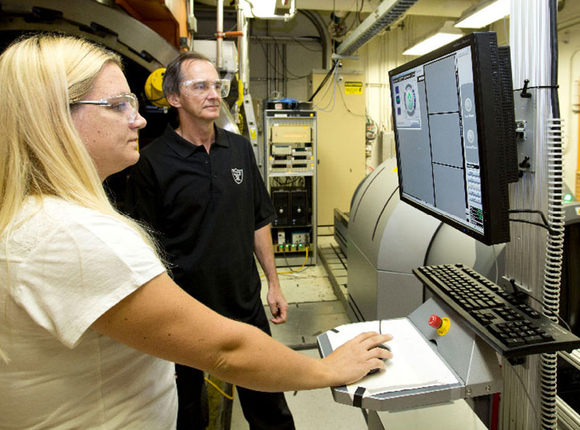

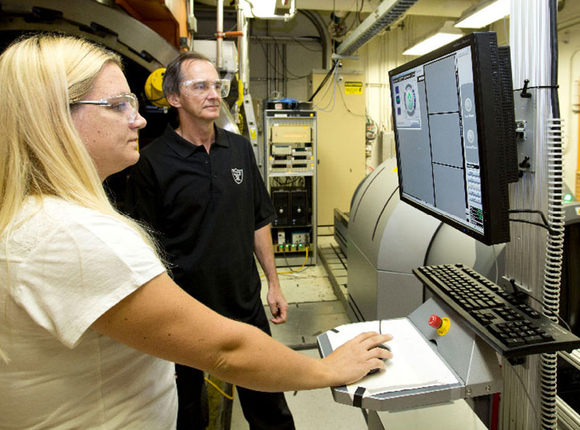

In late 2020, LLNL engineers and researchers accomplished their first key program level achievement in the W87-1 Modification Program, which will replace the W78 thermonuclear warhead. The W78 is nearing the end of its functional lifespan after 37 years perched atop the Air Force’s Minuteman III intercontinental ballistic missiles. The achievement is called the Customer Requirements Review, which is centered around the Department of Defense and National Nuclear Security Administration (NNSA) concurring that the system requirements are complete, clear and consistently understood between stakeholders. Upon completion, the U.S. ICBM force will consist of ICBMs with both the existing W87 warheads and W87-1 warheads.

Since the crucial role of the labs is to certify the safety, security and effectiveness of the nuclear warhead, and that it will function as expected when paired with its new delivery system, key areas of focus in the certification plan are ensuring the functional integration of the whole system, and that that warhead can survive anticipated flight environments.

Experiments are already underway at LLNL’s National Ignition Facility, the High Explosives Applications Facility and the Contained Firing Facility to verify that material choices and component designs will function as designed, and that the integrated system is able to hold targets at risk well into the future. LLNL physicists and engineers are also working to develop novel experimental platforms that can help lend confidence in complex supercomputer models used to support the design of the warhead.

Other Project Highlights

Pit Product Realization

To help ensure that NNSA production capabilities are able to meet weapons program needs, LLNL works closely with colleagues at the production plants. One area of focus has been ensuring that there are enough “pits” for the warheads. Read Full Article

Pit Product Realization

To help ensure that NNSA production capabilities are able to meet weapons program needs, LLNL works closely with colleagues at the production plants. One area of focus has been ensuring that there are enough “pits” for the warheads. Pits are the plutonium cores of a nuclear weapon that initiate the nuclear reactions that drive a nuclear weapon when they are compressed by the high explosives. Prior to completion, the W87-1 will require newly manufactured pits certified by NNSA.

The Pit Product Realization Team (PRT) is led by the Defense Technologies Engineering Division (DTED), which is largely responsible for Weapon Systems Engineering at LLNL. The team consists of members from LLNL, which serves as the design agency; Los Alamos National Laboratory; and Kansas City National Security Campus, which both serve as production agencies; and NNSA federal partners. Together, they are working to overcome challenges to mature production processes and equipment needed to reach the first production unit pit in 2023, which will support the W87-1 modification program.

The W87-1 Mod is in Phase 6.2 of its development, the second phase of the warhead acquisition program, in which LLNL studies the feasibility of the design options. These options include the implementation of modern safety and security features in the warhead, like insensitive explosives and fire-resistant capabilities designed to prevent detonation in even the most extreme accident scenarios.

Other Project Highlights

Engineers at LLNL Bolster ICBM Readiness

In March 2021, a joint test assembly (JTA) designed by LLNL and Sandia national labs was placed onboard an unarmed Minuteman III intercontinental ballistic missile launched from Vandenberg Air Force Base in California. Read Full Article

Engineers at LLNL Bolster ICBM Readiness

In March 2021, a joint test assembly (JTA) designed by LLNL and Sandia national labs was placed onboard an unarmed Minuteman III intercontinental ballistic missile launched from Vandenberg Air Force Base in California. The ICBM test launch program is part of engineering’s technology maturation efforts validating and verifying the safety and readiness of the weapon system.

Angela Cook, W87-0 project engineer and system manager at LLNL, said the components inside the W87-0 stockpile flight test are a combination of stockpile return hardware, mock hardware and instrumentation assemblies. “LLNL flies JTAs a few times a year and we collect data about system performance as part of the nuclear weapons stockpile stewardship program,” she said. “The data from these flight tests is analyzed by both LLNL and Sandia and incorporated in our respective annual warhead assessments for the W87-0.”

LLNL’s Air Force Reentry Systems Group (AFRS Group) is responsible for overseeing warhead disassembly and inspection of LLNL components, where selected weapons are reconfigured into JTAs and rebuilt to represent the original build to the maximum extent possible while replacing nuclear material components with surrogate material. The AFRS Group ensures that the W87-0 stockpile is aging appropriately, and that it remains fully qualified and ready when the W87-0 becomes the first warhead fielded on the new Ground Based Strategic Deterrent missile, expected to launch in the next few years.

Other Project Highlights

Related Facilities and Centers

Advanced Manufacturing Laboratory

The Advanced Manufacturing Laboratory (AML) is part of the Livermore Valley Open Campus (LVOC)—a 110-acre open and unclassified innovation hub for stimulating collaborative projects with external partners in government, industry, and academia. LVOC is a joint initiative of the NNSA, LLNL, and Sandia National Laboratories.

Advanced Manufacturing Laboratory

The Advanced Manufacturing Laboratory (AML) is part of the Livermore Valley Open Campus (LVOC)—a 110-acre open and unclassified innovation hub for stimulating collaborative projects with external partners in government, industry, and academia. LVOC is a joint initiative of the NNSA, LLNL, and Sandia National Laboratories.

Center for Advanced Signal and Image Sciences

The Center for Advanced Signal and Image Sciences (CASIS) establishes a forum where research scientists and engineers can freely exchange information and ideas, focused on the areas of the signal and image sciences.

Center for Advanced Signal and Image Sciences

The Center for Advanced Signal and Image Sciences (CASIS) establishes a forum where research scientists and engineers can freely exchange information and ideas, focused on the areas of the signal and image sciences.

The Center for Bioengineering applies its tools and principles to complex, biological systems. Our mission challenge is to enable transformational solutions to counter biological threats and increase national resilience.

The Center for Bioengineering applies its tools and principles to complex, biological systems. Our mission challenge is to enable transformational solutions to counter biological threats and increase national resilience.

Center for Engineered Materials and Manufacturing

The Center for Engineered Materials and Manufacturing (CEMM) spans multiple laboratories, innovating additive manufacturing techniques to create structural and functional materials with novel capabilities. The center also serves as an incubator, training future additive manufacturing talents.

Center for Engineered Materials and Manufacturing

The Center for Engineered Materials and Manufacturing (CEMM) spans multiple laboratories, innovating additive manufacturing techniques to create structural and functional materials with novel capabilities. The center also serves as an incubator, training future additive manufacturing talents.

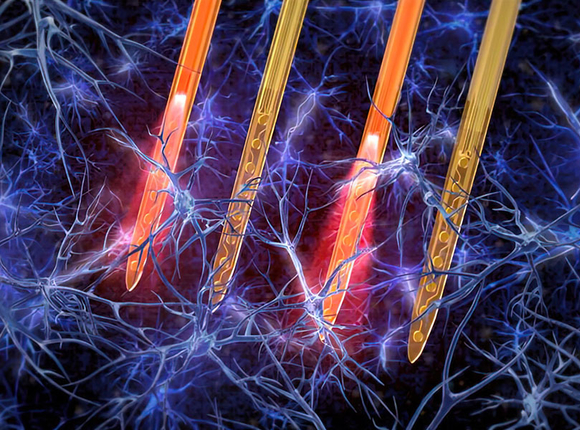

Center for Micro Nano Technology

The Center for Micro Nano Technology (CMNT) works with materials, devices, instruments, and systems that require microfabricated components, including microelectromechanical systems, electronics, photonics, micro- and nanostructures, bioimplantable devices, and micro- and nanoactuators.

Center for Micro Nano Technology

The Center for Micro Nano Technology (CMNT) works with materials, devices, instruments, and systems that require microfabricated components, including microelectromechanical systems, electronics, photonics, micro- and nanostructures, bioimplantable devices, and micro- and nanoactuators.

Nondestructive Characterization Institute

Nondestructive characterization aims to understand the internal physical properties of a material, component, or system without causing damage. The Nondestructive Characterization Institute advances the fields of non-destructive evaluation and characterization through collaborative research and development applied to real-world national security problems.

Nondestructive Characterization Institute

Nondestructive characterization aims to understand the internal physical properties of a material, component, or system without causing damage. The Nondestructive Characterization Institute advances the fields of non-destructive evaluation and characterization through collaborative research and development applied to real-world national security problems.

Take Your Place on the

Leading Edge

Our work is fundamentally transforming the field of advanced manufacturing and materials engineering. Learn more about what a career with LLNL Engineering might have in store for you.