Optics and Photonics

Harnessing the Power of Light

Photonics is the science and application of light in which it is generated and manipulated to perform various functions through transmission, modulation, emission, amplification, and sensing. Optics and photonics are complementary fields, with lasers and fiber optics being some well-known applications: fiber-optic data transmission of data, for example, is the basis for the internet.

The world's foremost laser and photonics engineers are assembled at LLNL for research, design, operation, and testing to support missions including nuclear deterrence, homeland security, energy security, and defense. Uncharted territory is explored here daily, especially at NIF (the National Ignition Facility), where experiments support the safety, security, and reliability of the national stockpile.

Optics and Photonics is central to NIF’s work, as we develop, fabricate, and evaluate new materials for advanced laser systems and the experiments conducted on them. To meet those needs, we have designed precisely fabricated fusion and high energy density physics micro-targets, ultra-thin polymer films that can support target capsules, and polymer coatings that can withstand extreme environments.

Our teams also develop and engineer high-energy-density plasma diagnostics in the optical, X-ray, and nuclear regimes to measure the results of NIF experiments. Optics and Photonics at LLNL innovates in diffractive optics, advanced laser crystals, fiber lasers, and transparent ceramics.

Please do not alter or edit this area. This generates the skewed image boxes.

border-box-0

border-box-1

border-box-2

Project Highlights

LLNL is a leader in developing advanced high-energy, high-average-power, pulsed and ultrafast laser systems as well as high-resolution space telescopes and high-performance optical lenses.

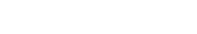

NIF's Optics Meet the Demands of Increased Laser Energy

If Lawrence Livermore National Laboratory (LLNL)’s National Ignition Facility (NIF) were a race car, it would run at the redline most of the time. Pushing the envelope on optics makes that possible.Read Full Article

NIF's Optics Meet the Demand of Increased Laser Energy

If Lawrence Livermore National Laboratory (LLNL)’s National Ignition Facility (NIF) were a race car, it would run at the redline most of the time.

“NIF is the only laser system that intentionally operates above the laser damage growth threshold,” said Tayyab Suratwala, Optics and Materials Science & Technology program director. “We operate the laser at a power and energy level for which we can repair the optics at an acceptable rate.”

Pushing that envelope was an important enabler for NIF to achieve ignition on Dec. 5, 2022. Since NIF became operational in 2009, the LLNL optics team has persisted in hardening the optics to withstand ever-increasing laser energy, as NIF routinely exceeded its design specification of 1.8 megajoules and the debris that results from every experiment.

“Working in optics on NIF is like peeling an onion that is always growing,” Suratwala said. “Each time we overcome a challenge, we turn up the laser energy and create new challenges.”

The latest solution to the challenge of higher laser energy — a record 2.05 megajoules delivered in the ignition shot — is the fused silica debris shield or FSDS.

A shield for the shield

About five years ago, LLNL solved one intractable problem when researchers discovered that the disposable debris shield (DDS), which protects more valuable optics in the final optics assembly from debris, was itself a source of debris. After considering several possible solutions, including changing the DDS material, the scientists landed on adding the FSDS to the final optics assembly.

The FSDS became a shield for another shield — in this case for the grating debris shield (GDS), which is so valuable it is repeatedly repaired to extend its life as much as possible. With the optics recycling loop strategy, debris-induced laser-damaged GDS's and the wedged focus lens optics are removed, repaired and returned to NIF at a pace of about 40 optics a week.

“The FSDS reduced the number of damage sites on the GDS by 98%,” said staff scientist Chris Miller. “Our installed optics are lasting three times longer. And it allows us to use a thorough recycle process.”

Before, the team only repaired GDS damage sites that were 50 microns or larger. With less damage overall, they can repair sites as small as 10 microns.

“With our optics lasting longer, we are better able to operate the laser at higher energy levels,” said Optics Damage S&T Group Leader Wren Carr.

A complex implementation

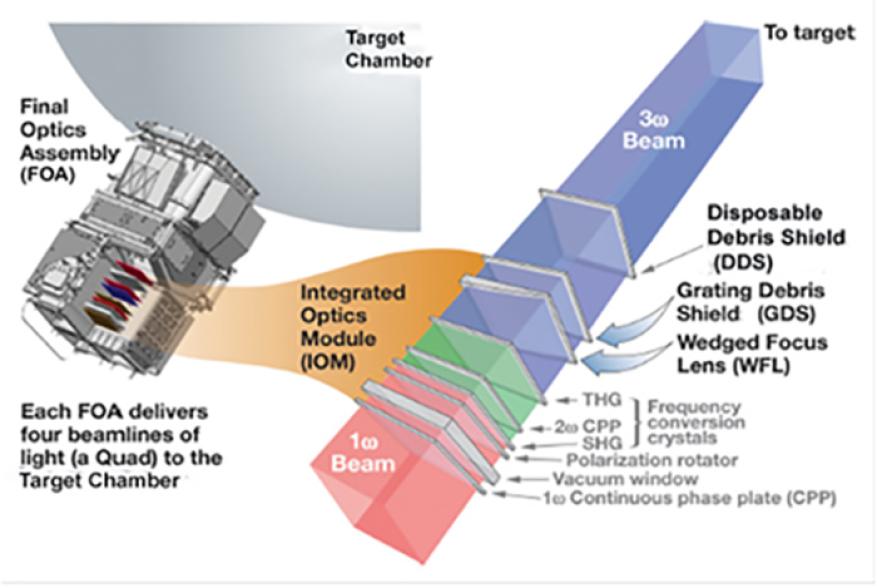

Adding the first major optic to NIF was no simple task. Ramping up production of the FSDS brought together many specialties including optical scientists, engineers, programmers and procurement. The team tackled challenges like developing image analysis software to evaluate damage on the new optic and increasing throughput in the Optical Processing Facility (OPF).

“Thanks to the booming semiconductor industry, there is more demand for fused silica,” said materials scientist Lana Wong. As the component engineer for the DDS and FSDS, she led the effort to identify and qualify multiple fused silica vendors to ensure an adequate supply chain.

The FSDS was initially installed on 48 beamlines in 2021 and on 80 more a year later. Before that transition, the OPF processed four optics a week.

“We tripled production, adding another eight FSDS optics per week to our regular workload,” said process engineer Diana VanBlarcom. “It meant reworking recipes for cleaning and coating, reengineering equipment to hold multiple FSDS optics instead of one and updating control systems, to name a few (upgrades).”

Installing the FSDS into NIF affected every area of operation. It required reprogramming NIF’s control system, the complex software that orchestrates some 66,000 control elements; designing and executing an efficient install and deinstall process; and developing processes for in-situ monitoring and removal criteria.

The FSDS went into a slot that had previously housed a metal shutter. Before each shot, this tray was moved out of the laser path.

“It was a huge change, telling the laser to shoot through an area that previously it was told never to shoot through,” said Nathan Ruiz, FSDS system manager. “Every technician working on NIF is now well-versed in the FSDS.”

The operation brought together all the facility teams: Facility and Infrastructure Systems (FinS), Laser-Alignment System Engineering (LASE), Laser Science and Systems Engineering (LSSE), the Optics Assembly Building (OAB), Optics & Materials Science & Technology (OMST), NIF&PS Control Systems (NCS), Radiation Operations, Shot Operations and Total Online Procurement Systems (TOPS).

“On NIF, there is no margin for error. There were multiple layers of checks and balances,” Ruiz said. “And we did it right every time.”

The FSDS Implementation Team was recognized for their effort with a Department of Energy Secretary’s Honor Achievement Award for the successful implementation and production operation of FSDS optics.

Optics improvements continue

The FSDS built on earlier advances like the Advanced Mitigation Process (AMP), a chemical-etching method that removes damage precursors. AMP was first deployed in 2014 and revamped in 2017. Also in 2017, the optics team began using an anti-reflective coating on the GDS to prevent it from reflecting excess light back to other optics.

“From investigating a problem to deploying a solution on the NIF optics, it’s about a five- or six-year process,” Suratwala said. “We are seeing these solutions pay off in a big way.”

Another problem under investigation is the pedestal beams, the 32 beams along the bottom of NIF’s target chamber.

“The optics in those lower beamlines experience more debris damage, which we can attribute to some degree to gravity,” Carr said. “As the debris trickles down to the pedestal beams, it slips into small openings and finds its way through cracks and gaps.”

The FSDS won’t be installed in the pedestal beams until the NIF operations teams can significantly bring down the damage rate. They are working on mechanical debris shielding, which has been partially deployed on the 32 lower beamlines.

Carr is confident that the team will continue to make progress with the mechanical debris shielding and against other challenges, such as how to make coatings stick better to the GDS and why debris damage also is higher on the upper 32 beams of NIF.

“Our job is never done, but that’s what makes it exciting,” he said.

Vera C. Rubin Telescope

In September 2021, LLNL engineers completed delivery of six optical components for a telescope expected to observe 20 billion galaxies from the Rubin Observatory in Chile.Read Full Article

Vera C. Rubin Telescope

In September 2021, LLNL engineers completed delivery of six optical components for a telescope expected to observe 20 billion galaxies from the Rubin Observatory in Chile. The project has been underway for about 10 years and involves industrial partners who did much of the fabrication. It is anticipated that the resulting Legacy Survey of Space and Time Camera (LSSTCam), will start imaging the southern sky in 2024.

A key feature of the LSSTCam’s optical assemblies will be its three lenses, one of which is the world’s largest high-performance optical lens ever fabricated, at 5.1 feet (1.57 meters) in diameter. The 8.4-meter telescope at Rubin Observatory will take digital images of the entire visible southern sky every few nights, revealing unprecedented details of the universe and helping unravel some of its greatest mysteries. During a 10-year time frame that will detect about 20 billion galaxies, the telescope will create a time-lapse "movie" of the sky.

This data will help researchers better understand dark matter and dark energy, which together make up 95 percent of the universe, but whose makeup remains unknown, as well as study the formation of galaxies, track potentially hazardous asteroids and observe exploding stars. The telescope’s camera will capture full-sky images at such high resolution that it would take 1,500 high-definition television screens to display just one picture.

Other Project Highlights

Related Facilities and Centers

Advanced Manufacturing Laboratory

The Advanced Manufacturing Laboratory (AML) is part of the Livermore Valley Open Campus (LVOC)—a 110-acre open and unclassified innovation hub for stimulating collaborative projects with external partners in government, industry, and academia. LVOC is a joint initiative of the NNSA, LLNL, and Sandia National Laboratories.

Advanced Manufacturing Laboratory

The Advanced Manufacturing Laboratory (AML) is part of the Livermore Valley Open Campus (LVOC)—a 110-acre open and unclassified innovation hub for stimulating collaborative projects with external partners in government, industry, and academia. LVOC is a joint initiative of the NNSA, LLNL, and Sandia National Laboratories.

Center for Advanced Signal and Image Sciences

The Center for Advanced Signal and Image Sciences (CASIS) establishes a forum where research scientists and engineers can freely exchange information and ideas, focused on the areas of the signal and image sciences.

Center for Advanced Signal and Image Sciences

The Center for Advanced Signal and Image Sciences (CASIS) establishes a forum where research scientists and engineers can freely exchange information and ideas, focused on the areas of the signal and image sciences.

Center for Engineered Materials and Manufacturing

The Center for Engineered Materials and Manufacturing (CEMM) spans multiple laboratories, innovating additive manufacturing techniques to create structural and functional materials with novel capabilities. The center also serves as an incubator, training future additive manufacturing talents.

Center for Engineered Materials and Manufacturing

The Center for Engineered Materials and Manufacturing (CEMM) spans multiple laboratories, innovating additive manufacturing techniques to create structural and functional materials with novel capabilities. The center also serves as an incubator, training future additive manufacturing talents.

Center for Micro Nano Technology

The Center for Micro Nano Technology (CMNT) works with materials, devices, instruments, and systems that require microfabricated components, including microelectromechanical systems, electronics, photonics, micro- and nanostructures, bioimplantable devices, and micro- and nanoactuators.

Center for Micro Nano Technology

The Center for Micro Nano Technology (CMNT) works with materials, devices, instruments, and systems that require microfabricated components, including microelectromechanical systems, electronics, photonics, micro- and nanostructures, bioimplantable devices, and micro- and nanoactuators.

Take Your Place on the

Leading Edge

Our work is fundamentally transforming the field of advanced manufacturing and materials engineering. Learn more about what a career with LLNL Engineering might have in store for you.