Center for Engineered Materials and Manufacturing (CEMM)

Printing the Infinite Future

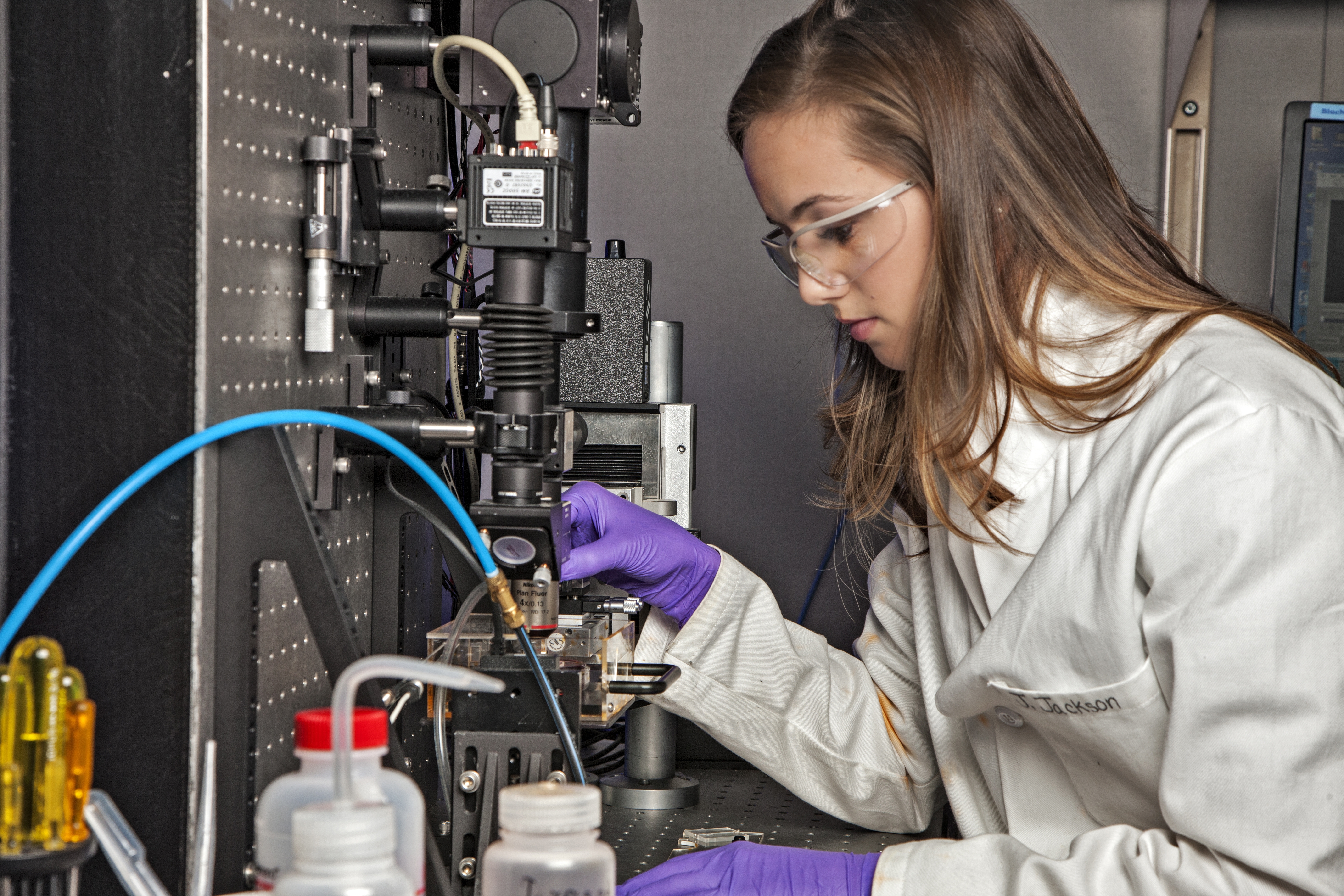

From ultralight materials that can withstand more than 160,000 times their weight to printed glasses with controllable compositions to biological materials for drug delivery and environmental remediation, The Center for Engineered Materials and Manufacturing (CEMM) is pioneering the field of additive manufacturing (AM), also known as 3D printing.

Our History

Established in 2014, The Center for Engineered Materials and Manufacturing (CEMM) builds on the rich history of additive manufacturing at LLNL. CEMM was established in response to an acute need for more focused efforts in a rapidly-emerging field, and it continues to span multiple laboratories at LLNL. Accordingly, it draws on the various capabilities of the original contributors and is equipped with customized and industrial-grade additive manufacturing equipment for polymers, ceramics and metals, in addition to on-site characterization capabilities.

Please do not edit anything in this area.

Our Mission

The Center for Engineered Materials and Manufacturing (CEMM) is committed to innovating additive manufacturing techniques to create structural and functional materials with new capabilities for applications in defense, energy, infrastructure, medicine and beyond. The center leverages knowledge from across disciplines to be a leader in all areas of additive manufacturing: tools and process development, materials synthesis and processing, architecture design and optimization and products properties characterization.

CEMM invests in the future by leading the digital transformation in manufacturing through partnerships with government, academia and industry. The center is also committed to teaching and training the next generation of AM talent.

Please do not alter or edit this area. This generates the skewed image boxes.

border-box-0

border-box-1

border-box-2

Collaborate with Us

Let’s make something incredible together

We’d love to explore what a collaboration with your organization might involve. Fill out the form below to get started.

Please don't edit this area