Center for Engineered Materials and Manufacturing (CEMM)

Crucial Resources, Infinite Promise

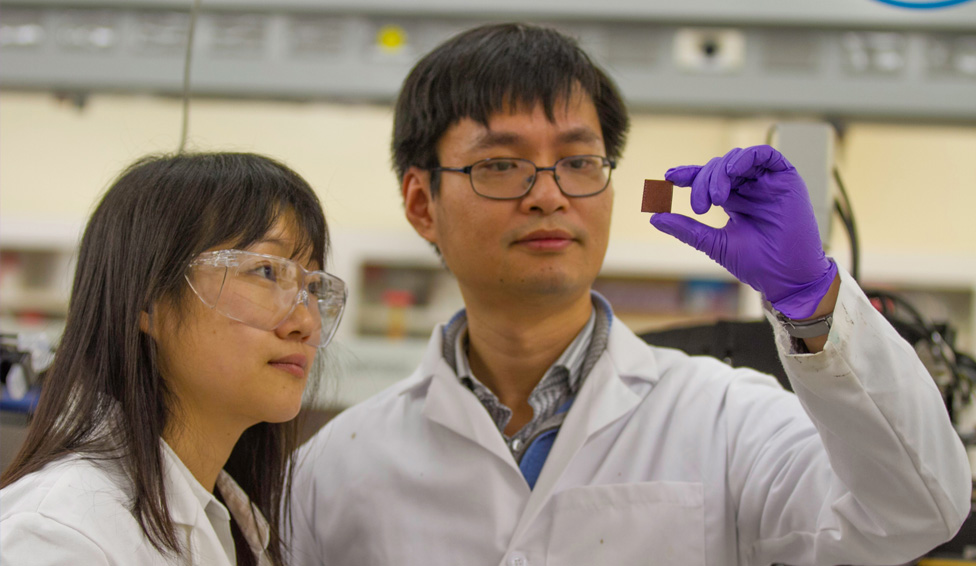

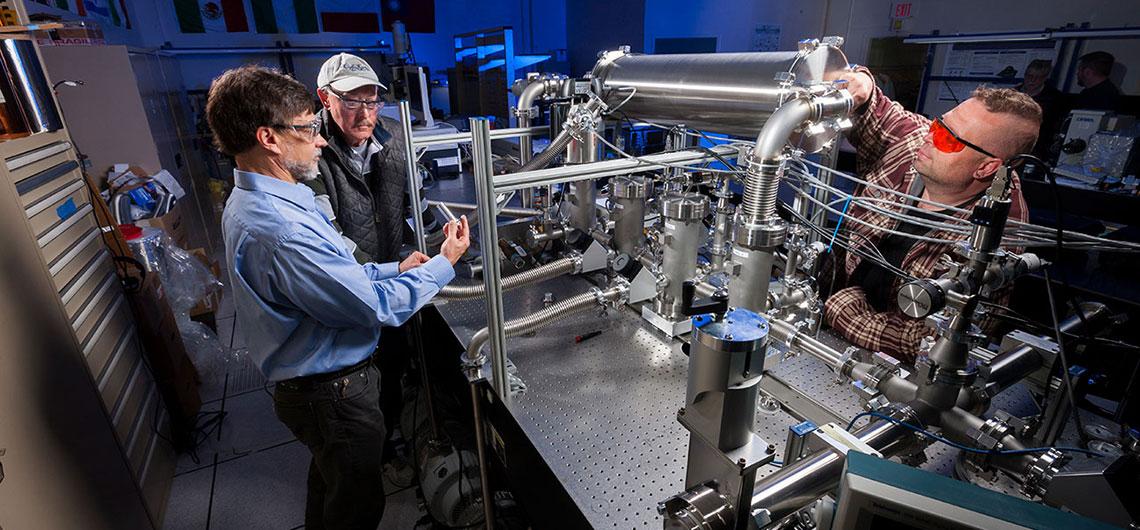

The Center for Engineered Materials and Manufacturing spans multiple buildings at Lawrence Livermore National Laboratory and has access to a variety of custom-built and state-of-the-art equipment, techniques, and capabilities to advance additive manufacturing technology. In addition to pioneering a variety of additive manufacturing techniques, we make use of the Lab’s considerable resources for design optimization, characterization, and high performance computing, among other specialized research and development tools.

Please do not alter or edit this area. This generates the image borders.

border-box-0

border-box-1

border-box-2

Technical Capabilities

- Additive Manufacturing (AM)

- Materials Synthesis and Processing

- Design and Optimization

- Characterization and Testing

-

Direct-ink writing (pictured)

-

Binder-jet printing

-

Fused deposition modeling

-

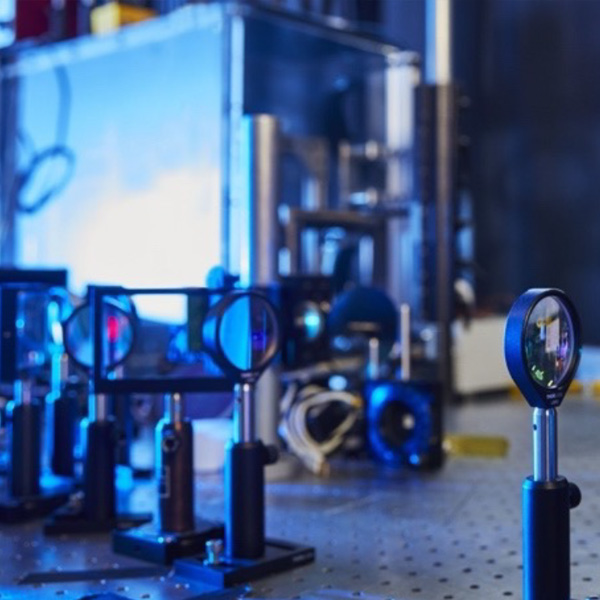

Projection micro-stereography (PmSL) (pictured)

-

Two-photon polymerization (TPP)

-

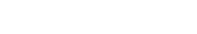

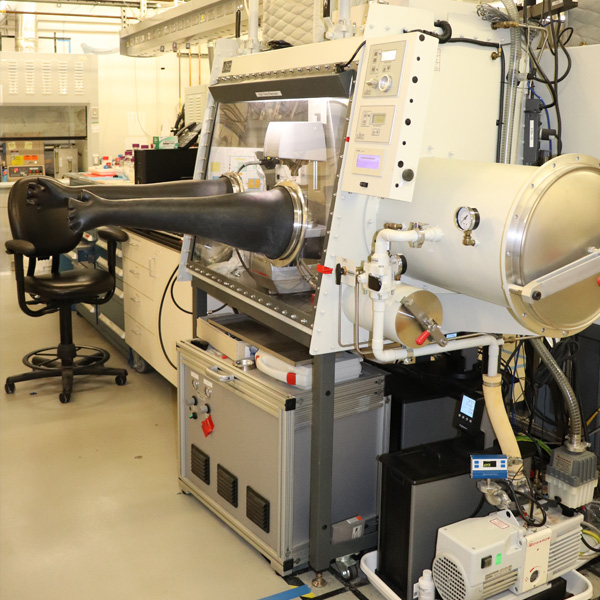

Selective laser melting (SLM) (pictured)

-

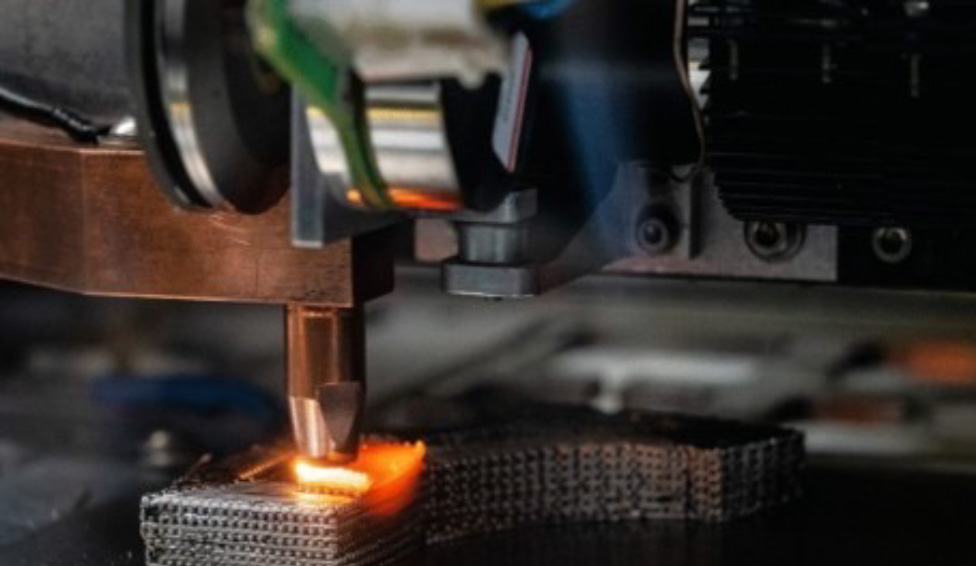

Electrophoretic deposition (EPD) (pictured)

-

Acoustic printing

Polymer, ceramic, metal and carbon-based materials colloidal processing, complex fluid processing, nanomaterials synthesis, etc.

Modeling and simulation of architected materials

- Access to scanning electron microscopy (SEM), transmission electron microscopy (TEM), atomic force microscopy (AFM), spectroscopy tools and small- and wide-angle x-ray diffraction facilities

- Access to the world-class LLNL high-performance computing (HPC) environment

Facilities and Equipment

AM Equipment

- Projection Microstereolithography (PmSL) systems

- Large-Area Projection Microstereolithography (LAPmSL)

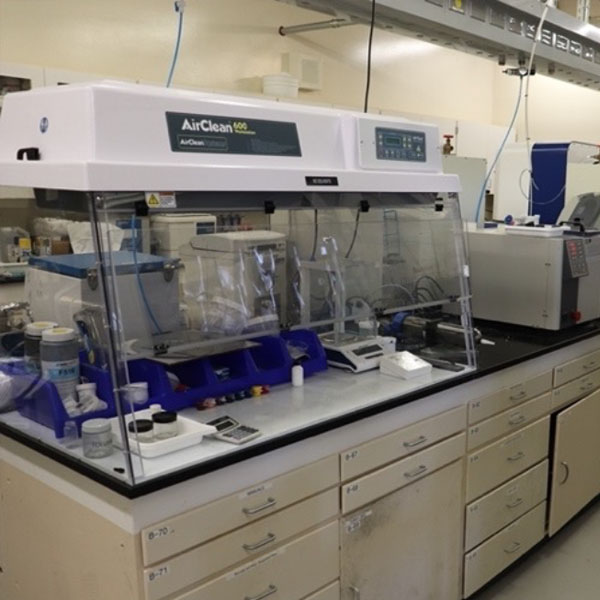

- Electrophoretic Deposition (EPD) system in which electrical deposition cell is integrated with high-powered, computer-controlled light source and fluid handling systems

- Direct Ink Writing (DIW) motion stages that can write areas approaching 0.5 m2 and speeds exceeding 20 cm/s, plus a custom-developed extrusion print head that mixes multiple materials

- Fused deposition modeling (FDM) machines

R&D Tools: Rheometers, laser-based micropipette puller, optical microscopes, orbital mixers, dynamic light scattering tool, combined differential scanning calorimeter and thermal gravimetric analyzer, ovens for thermal post-processing of fabricated structures

AM Equipment

- NanoScribe two-photon polymerization system

- SLM system that uses the powder-based SLM process and is equipped with high-speed cameras, two color pyrometry, and optical coherence tomography

- Custom-developed exploratory printing systems, including:

- Two-photon polymerization for high-speed nanoscale printing

- Volumetric AM that fabricates without any layers

- PmSL and LAPmSL systems

R&D Tools: Benchtop SEM, Instron mechanical testing equipment, Keyence optical surface profilometer, FTIR and UV vis spectroscopy, dynamic light scattering device for materials

HPC at LLNL

The Livermore Computing Complex consists of three facilities consisting of upwards of 50,000 square feel of computer room floor and over 40 megawatts of computational capacity to form the “third pillar” of research, alongside theory and experimentation. Producing cost efficient reams of data, HPC at LLNL serves all of the Lab’s programmatic missions. Learn more about our computing power at hpc.llnl.gov/about-us.

Other AM Equipment at LLNL

- 4 additional SLM metal powder-bed machines (2 Concept Laser, 2 SLM Solutions)

- An additional ExOne binder printer

- Multiple additional DIW extrusion systems with Aerotech motion hardware and control

- Multiple Stratasys Fortus FDM machines

- An Optomec Aerosol Jet system

- A polyjet machine

Systems Engineering

At the forefront of the final frontier

Our Systems Engineering teams cover many areas, from sensor development to space science engineering. Using advanced modeling tools plus optimization capabilities and uncertainty quantification, systems engineering strives to quantify and elucidate decision-making and to hone new technologies within the context of the systems they will impact.

Computational Engineering and Data Science

Modeling and simulation for national security

Computational Engineering and Data Science advances modeling & simulation, data-analytic tools, and entire fields of study, such as collaborative autonomy—all with the aid of LLNL’s massive computing facilities. Our work underpins and informs national security efforts throughout the Lab.

Collaborate with Us

Let’s make something incredible together

We’d love to explore what a collaboration with your organization might involve. Fill out the form below to get started.

Please don't edit this area