Center for Design Optimization (CDO)

Optimizing Complex Systems

The Center for Design and Optimization (CDO) optimizes the ever more complex systems governed by the nonlinear, dynamic, multiphysics, multifunctional and multiscale phenomena made possible by LLNL’s advanced manufacturing technologies.

As part of this effort we are developing the Livermore design optimization (LiDO) code. The LiDO code is used by engineers and designers to optimize their multifunctional systems, e.g., thermomechanical structures, multiscale structures, heat exchangers, and battery electrodes. LiDO uses LLNL’s High-Performance Computing (HPC) libraries to solve problems with ~109 design variables.

We are also developing black box optimization methods that can be used with our production codes and in experimental design scenarios. Some of these methods utilize machine learning to build surrogate models which are subsequently used in our gradient-based LiDO optimization; others rely on various direct search or heuristic methods.

CDO Capabilities

Center for Design Optimization capabilities include:

- Optimizing macroscopic structures with high fidelity simulations to ensure accurately predicted performance

- Designing metamaterials with unique mechanical, thermal and electromagnetic properties

- Maximizing performance of macroscopic structures by leveraging our optimized metamaterials

- Revolutionizing the design of energy, fluid, and chemical transport systems

What We’re Working On

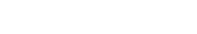

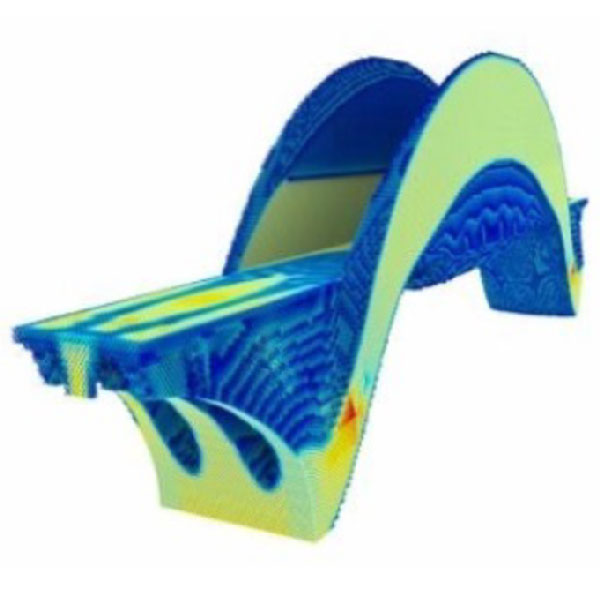

The structural design work the CDO performs is demonstrated by this drone chassis design. The structure must reside in the illustrated blue cross design. It is subjected to the 4 outer upward thrust loads, which are due to the propellers, and the downward center load, which is due to the payload and motor weight.

The objective is to distribute material throughout the design domain to maximize the structure’s stiffness subject to a maximum weight constraint. The LiDO software iterates through the design space to optimally distribute the material.

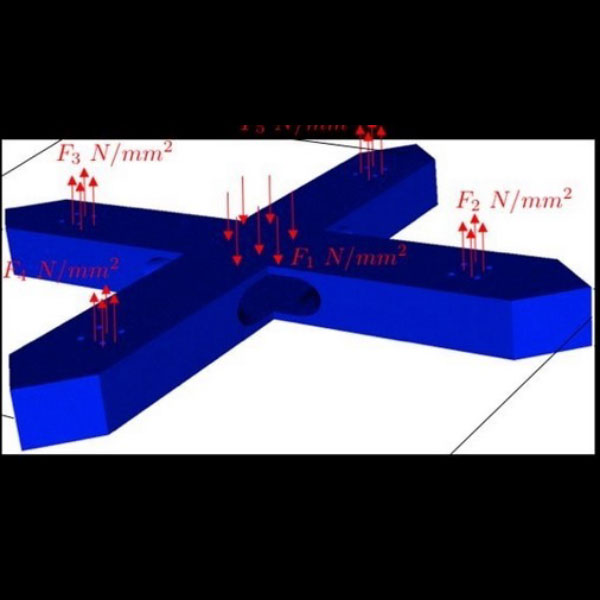

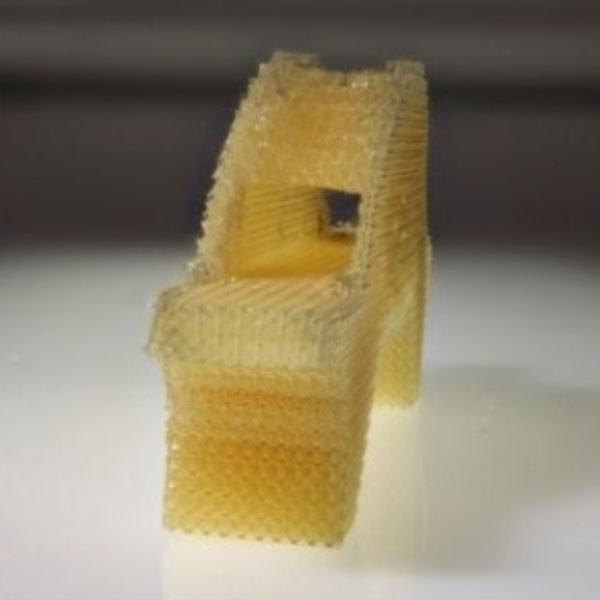

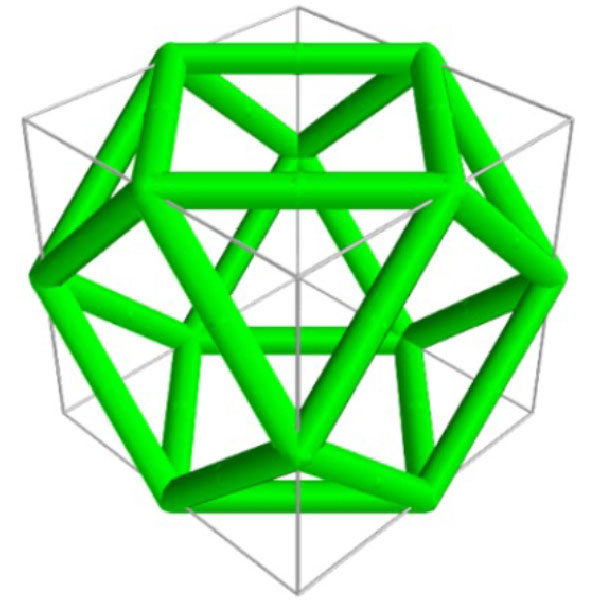

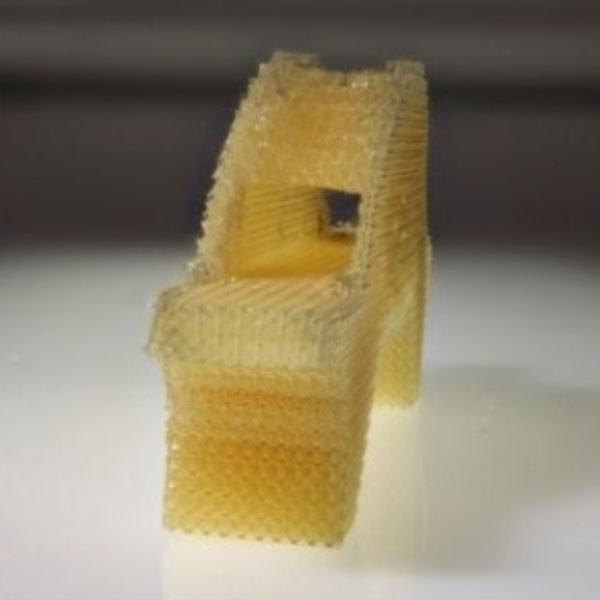

In LiDO’s multiscale design mode, the user specifies a unit cell type, i.e., building block, which will be used to construct a macroscopic structure. LiDO then spatially optimizes the unit cell’s relative density throughout the design domain to maximize the performance of the macroscopic structure.

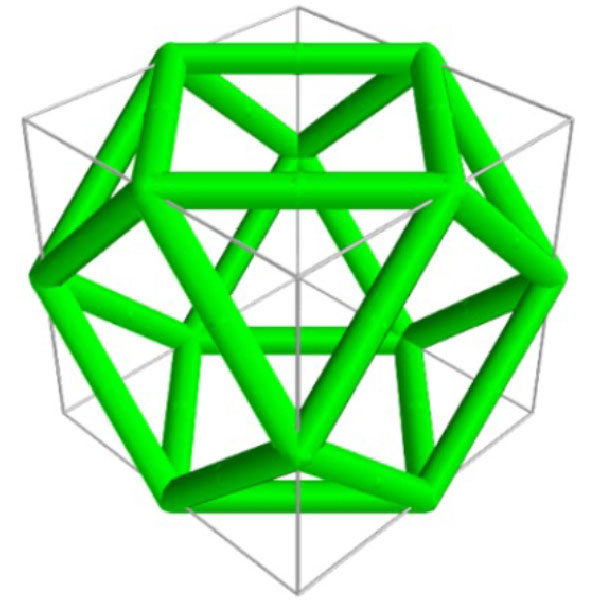

In this example, we make a bridge from the illustrated unit cell. As we change the relative density of the unit cell, we change its effective stiffness and strut diameter. We can thereby use large relative density unit cells in regions that will carry significant load, and small relative density unit cells in other regions, in order to save mass.

Interested in Collaborating? Email Us: eng-cdo-collab [at] llnl.gov (eng-cdo-collab[at]llnl[dot]gov)

Want to Partner with Us?

Let's make something incredible together

We'd love to explore what a collaboration with your organization might involve. Fill out the form below to get started.

Please don't edit this area