Apprenticeship

Training Expert Technicians

LLNL missions depend on specialized manufacturing capabilities not available outside the Laboratory. Manufacturing professionals make up about 10 percent of the Engineering workforce: they fabricate parts for LLNL to implement research and design innovations, all with a cost-effective, low-waste ethos.

LLNL's Machine Apprenticeship Program

Engineering’s 4-year Machinist Apprenticeship Program is California-certified, offers paid education plus training in the machine-tool trade, and provides the potential for a permanent job upon graduation.

Apprentices receive roughly 8,000 hours of education and experience, including hands-on training under journey-level mentors and supplemental instruction on technical theory. Program graduates earn a Journeyman Certificate issued by the State and/or U.S. Department of Labor.

At a place like this, there's always room to move up or learn more. The sky's the limit.

Machinist apprentice program grad

What Engineering Apprentices Do

-

Manufacture complex products under mentorship from senior machinists

-

Use high-end equipment to produce components for cutting-edge science

-

Rotate through a series of learning areas, performing hands-on machining

Apprenticeship Qualifications

-

A high-school diploma, GED, or equivalent, with completed shop math, mechanical drawing, agricultural engineering, or other relevant courses

-

A passing score on the LLNL apprentice aptitude exam

-

Basic knowledge of and experience with shop equipment, tools, procedures, and materials

-

Basic math skills, including geometry and trigonometry

-

A valid CA driver’s license, able to operate 6,000 lb. fork truck

-

Must be medically able to wear respiratory and protective equipment

-

The ability to pass drug tests and obtain top-secret government clearance

Check Out Our

Apprenticeship Openings

We accept 2-5 apprentices each year, keeping cohorts small to enable hands-on learning. Positions open in winter for a summer start.

See Yourself Here

Engineering has a full range of manufacturing and technical services to assist with LLNL program needs. The facilities that provide these services are collectively known as “The Manufacturing Service Center”—learn more below.

Mechanical Engineering Division (MED) Area Machine Shops

read more +

Mechanical Engineering Division (MED) Area Machine Shops are five machine shops open for use by all qualified Laboratory employees. MED’s resident journey-level machinist provides direct program support, manages each shop, oversees safe operations, and provides technical advice for users.

- Materials Process Engineer

- Mechanical Technologist

- Research Support Engineer

High Explosives Processing

read more +

The High Explosives Processing machinists at Site 300 are among the most skilled in the nation at machining high-explosive materials, employing conventional and computerized numerical controlled (CNC) machine tools for contact and remote machining.

- High Explosives Applications Facility Electrical Engineer

- Electronics Technologist

- Mechanical Technologist

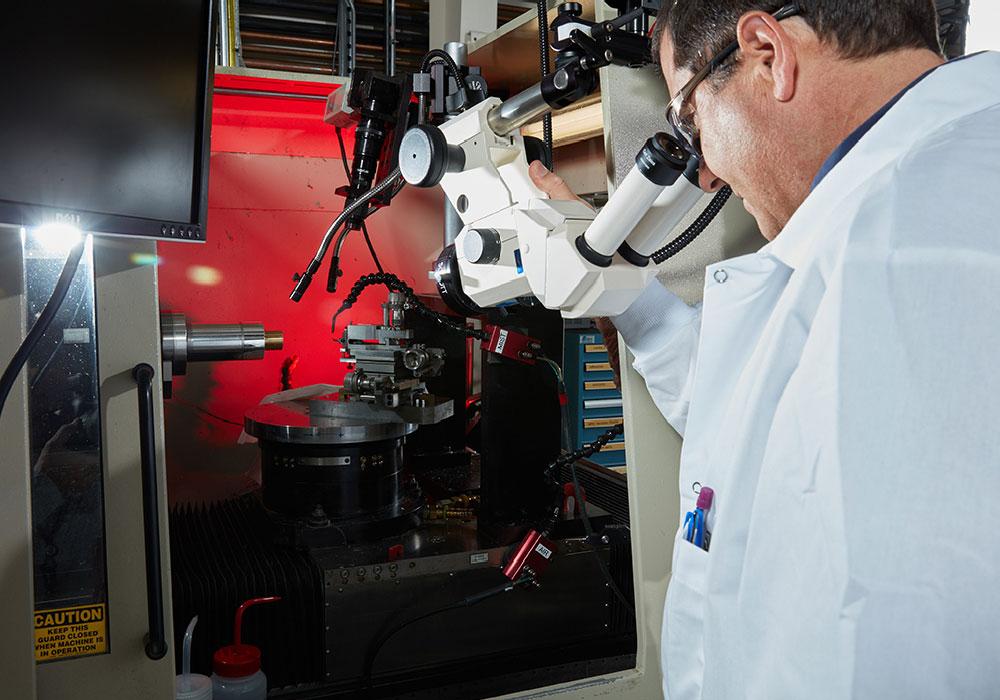

Dimensional Inspection Laboratory

read more +

The Dimensional Inspection Laboratory is a full-service center providing solutions for all metrology needs. Our facilities are in a controlled environment that accommodates a broad range of inert and radioactive materials. MED maintains a variety of world class metrology equipment.

- Optical Engineer

- Automation Hardware Engineer

- Assurance Manager

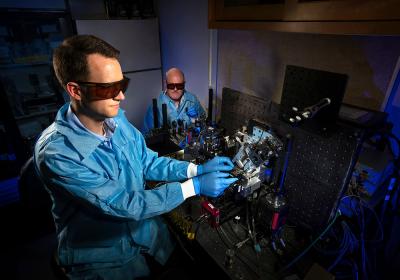

Laser Processing Facility

read more +

The Laser Processing Facility provides laser processes such as laser cutting and welding of material using 400W and 200W Nd:YAG pulsed lasers. Our personnel have extensive experience in prebuilt design assistance, weld joint designs, weld-preparation, and alternative manufacturing processes.

- Facilities Electrical Engineer

- Mechanical Test Engineer

- Mechanical Engineer

Main Bay Machine Shop

read more +

The Main Bay Machine Shop provides computerized numerical controlled (CNC) milling and CNC turning capacities. We also provide heat training, tool and cutter grinding, forming, vendor evaluation, project coordination, and consultation on manufacturing feasibility and process evaluation.

- Machine Tool Repairer

- Machinist

- Mechanical Technologist

Metal Finishing and Plating Shop

read more +

The Metal Finishing and Plating Shop is a chemical processing facility dedicated to providing electroplating, cleaning, and other chemical processes to Laboratory programs. The 6,500-square-foot facility houses processing tanks of up to 550-gallon capacity and offers more than 65 different processes.

- Machine Tool Repairer

- Sheet Metal Fabricator

- Supply Chain and Manufacturing/Fabrication Project Engineer

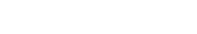

Optic Shop

read more +

The Optic Shop develops processes for onsite fabrication, liaises with vendors, and offers offsite inspections and technology transfer training. The Optic Shop has been a primary contributor to programs including target fabrication, the National Ignition Facility, and the Mercury Laser system.

- Automation Hardware Engineer

- Optical Engineer

- Photonics/Laser Electro-Optics Technologists

Precision Machining Facility

read more +

The Precision Machining Facility provides high quality precision parts. A wide variety of materials from plastics to exotic/precious metals are machined using traditional and non-traditional manufacturing processes to produce parts with tolerance requirements in the 0.0001-inch or less range.

- Machinist

- Product Realization Engineer

- Target Fabrication Machinist

Sheetmetal Shop

read more +

The Sheetmetal Shop provides standard sheet metal fabrication processes such as shearing, braking, rolling, sawing, forming, nibbling, punching, tubing and spring bending, riveting, brazing, spot welding, and tungsten inert gas (TIG) welding as well as computerized numerical controlled (CNC) laser cutting

- Materials Process Engineer

- Sheet Metal Fabricator

- Technical Coordinator

Special Materials Machining Facility (SMMF)

read more +

The Special Materials Machining Facility (SMMF) machines toxic and low-level radioactive materials. SMMF has T-based lathes and large, five-axis milling capability, as well as conventional and computer numerically controlled (CNC) lathes and mills, plunge and wire electrical discharge machines (EDM), and two jig-boring machines.

- Machine Tool Repairer

- Mechanical Technologist

- Target Fabrication Machinist

Target Fabrication Shop

read more +

The Target Fabrication Shop’s ultra-precision machining capabilities creates targets for the National Ignition Facility, Z machine, and the Omega Laser Facility. Aerogels, exotic or precious metals, radioactive material, and more are micro-machined under conventional and diamond turning processes.

- Diagnostic Systems Engineer

- Pulsed Power Engineer

- Target Fabrication Engineer

Water Jet Shop

read more +

The Water Jet Shop is an integral part of LLNL’s Mechanical Engineering Division (MED) manufacturing facility and provides unique material cutting capabilities. Its machines do not induce stress or thermal inconsistencies into the material being cut.

- Machinist

- Mechanical Systems Engineer

- Mechanical Technologist

Weld Shop

read more +

The Weld Shop provides fabricated metal parts, heavy weldments, and assemblies varying in thicknesses from 1/8” to several inches. The shop works on most nonhazardous metal alloys and has a material yard and 10-ton crane for added flexibility and quick turnaround.

- Machine Tool Repairer

- Mechanical Technologist

- Sheet Metal Fabricator

Postdoctoral & Fellowship

read more +

Pushing the boundaries of scientific research.

We offer postdoctoral appointments that allow recent PhD graduates to further their research and collaborate with our wold-class scientists. For more information, see the Postdocs page.

Possible Roles

- Postdoctoral researcher

- Lawrence fellow

- High Energy Density Science (HEDS) fellow

- Fernbach fellow

Magi Mettry

Postdoctoral Researcher

"Balance and moderation in all you do is the path to a happy and fulfilling life."

I love the balance in the LLNL work environment. This balance comes in two forms: work-life balance, and balance between different research projects. Moving here I immediately observed a healthy work environment and a great and supportive team from mentors to division leaders!

Public Affairs & Communications

read more +

Communicating our work to the world.

Our public affairs and communications teams focus on distilling and sharing our cutting-edge innovations and complex scientific ideas, making them accessible to a wider audience and inspiring the public to get involved in our research.

Possible Roles

- Communications manager

- Public information officer

- Social media strategist

- Graphic designer

- Photographer

Brian Chavez

Graphic Design Associate

"I’m shoulder to shoulder with some of the smartest peeps in the world."

It actually may surprise you to see how many positions they offer that may fit your skill set. And don’t let that “degree” stop you. Even if you don’t have a degree, you may just have what they want in skill. Ain’t bad for a high school graduate and veteran with some college.

Security

read more +

Keeping you and our nation safe.

Our security team ensures the uninterrupted protection of our physical assets, information, employees, and guests, allowing the Laboratory to fulfill the mission of protecting national security. Our team has extensive knowledge and experience in tactical and operational protection planning, information security, personnel security, physical security, performance assurance, and training.

Possible Roles

- Security police officer

- Classified matter and protection specialist

- Physical security specialist

- Electrician and locksmith

- Compliance and assurance specialist

- Investigator

- CCTV and call center dispatch operator

- Training and curriculum designer

Students

read more +

Surrounding you with a culture of possibility.

Learn, grow, and explore while working here as an intern—and have fun along the way. You will have access to cutting-edge technologies that are transforming the world for the better and the opportunity to work and learn with world-class scientists and engineers. For more information, visit our Students page.

Possible Roles

- Undergraduate student intern

- Graduate student intern

- Trainee

Logan Echeveria

Summer Intern

"My passion for science grew more and more every day I was at the Lab."

I was a summer student in Materials Engineering Division during the summer of 2019. Here, I worked on a biochemical sensor project. I was able to contribute technical knowledge developed at my university in classes such as optics, signal processing, and electromagnetics. I sharpened my engineering skills by working in a laser laboratory and I was even introduced to an entirely new discipline by working part time in a bio lab.

Being a summer student at Lawrence Livermore National Laboratory gave me the opportunity to explore research areas in my discipline, to network with professionals in my field, and to grow as a scholar. Outside of research, I enjoyed all of the events put on for summer students (like a BBQ and trivia) and touring the facilities on the LLNL campus.

Supply Chain

read more +

Helping you get what you need.

Our supply chain staff work tirelessly to ensure everyone on campus has what they need when they need it. We focus on building professional partnerships with customers, suppliers, and colleagues.

Possible Roles

- Subcontracts analyst

- Cost price analyst

Alberto Rocha

Contracts Analyst

"A team is not a group of people that work together. A team is a group of people that trust each other. I am blessed to find this at LLNL."

Working hard for something we don’t care about is called stress; working hard for something we love is called passion. Come to LLNL where people pull together as a team. You will love it!

Need more information? Contact Larry Sage at sage5 [at] llnl.gov (sage5[at]llnl[dot]gov) or (925) 423-8327 OR Jason Carroll at carroll17 [at] llnl.gov (carroll17[at]llnl[dot]gov) or (925) 424-4369.