A Lawrence Livermore National Laboratory (LLNL) team recently described a new approach to developing models of crystal plasticity by calibrating their models against high-fidelity molecular dynamics (MD) simulations. To illustrate their approach, they focus on body-centered cubic (BCC) single crystal tantalum (Ta) which was modeled with a quantum-accurate interatomic potential.

In a recent paper titled “Crystal plasticity model of BCC metals from large-scale MD simulations,” the team, led by Nicolas Bertin found that understanding and accurate modeling of metal plasticity is of critical importance in many engineering and industrial applications, from building reliable bridges to fabricating micro-conductors. Since metals are mostly comprised of polycrystalline aggregates, their behavior is largely dictated by the way the individual crystals that make up their microstructure respond and deform when exposed to various conditions. To make predictions at the macroscopic scale, researchers have invested a great deal of effort into developing crystal plasticity (CP) models that predict the behaviors of single crystals that are the basis for various metals.

The authors note that, while these efforts have not been unfruitful, with a variety of models being available, the behavior of these single crystals remains remarkably challenging to capture accurately.

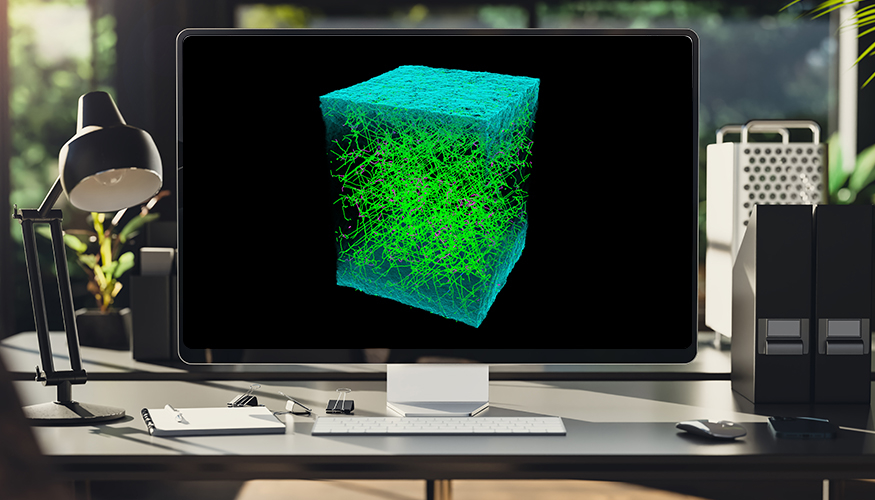

The difficulty, they say, lies in the complexity of the physics underlying metal plasticity — a constellation of interconnected dislocation networks affecting each other’s behavior and motion, which is a difficult thing to fully model.

Fortunately, the increased availability and decreasing costs of high-performance computing have made possible ever-larger and more accurate direct atomistic simulations of crystal plasticity over an extended range of strain rates and interatomic potentials. Coupled with an increase in specialized post-processing tools, MD can simulate and represent different conditions under which the metals deform, and which hint at the underlying atomistic dynamics that gives rise to the mechanical behavior at the crystal plasticity level.

The achievement the paper describes lies in developing a simplified, cross-scale calibration model that uses MD simulations as a point of comparison — a success made possible by LLNL’s enormous high performance computing (HPC) resources.

The number of MD simulations used in this project led the researchers to modify basic assumptions about CP models. Insofar as the treatment of slip crystallography remains an unsettled issue in BCC metals, the authors took the novel step of abandoning the fixed set of slip systems typically used to model plasticity in BCC at the CP scale. This traditional approach was found to be inadequate for describing high-rate plasticity in BCC tantalum while also rendering predictive models overly complex. Instead, this research, as the authors put it, “only consider[s] the behavior of the dislocations associated with each of the four Burgers vectors.”

The researchers take this approach because their own MD simulations show dislocation links being non-planar and unassignable to a given slip plane — a combination of factors that calls into question whether slip systems can accurately model BCC crystals at all. Effectively, the paper redefines slip modes. Next, the dislocation density evolution of these modes correlates directly with crystal rotation and flow stress, which adequately describes the crystals’ behavior in all orientations. Finally, pinning the number of slip modes to the Burgers vectors reduces the number of slip modes and thereby drastically simplifies the equations used to create the modeling.

The resulting simplified, phenomenological CP model was then calibrated to the existing large-scale MD simulations by matching the evolution of the dislocation density and by establishing parameters for the slip rate “by least-squares fitting of the saturated flow stress and yield stress values,” according to the paper.

The team found that agreement between the CP and MD data was close and the model successfully captured the effects of loading orientation, tension and compression asymmetry, strain rate and temperature. According to the paper: "Although the dislocation density was well predicted for all four crystal orientations, the flow stress for two orientations is slightly under-predicted by the CP model, which was also the case for compression. Crystal rotations for all orientations are correctly captured for all four crystal orientations.”

The authors conclude that the work demonstrates the benefits of a cross-scale approach wherein “key qualitative behaviors and mechanisms can be uncovered in large-scale atomistic simulations and then incorporated into CP via refined model forms.”

As for the work’s future prospects, the authors acknowledge that, while they focus exclusively on BCC tantalum crystal behavior, the cross-scale calibration and CP framework they describe should transfer to other BCC metals by tweaking the model parameters against MD data, as they did.

The work described in the publication was funded by an LLNL Laboratory Directed Research and Development Exploratory Research project, with the MD simulations having been enabled by a Computing Grand Challenge allocation that furnished the research team with the HPC node-hours needed to run this resource-heavy project.

–Aimee Fountain